Technology

Seeing is understandingThe government uses BGC Engineering’s augmented reality software for community consultation for the Giant Mine Remediation Project

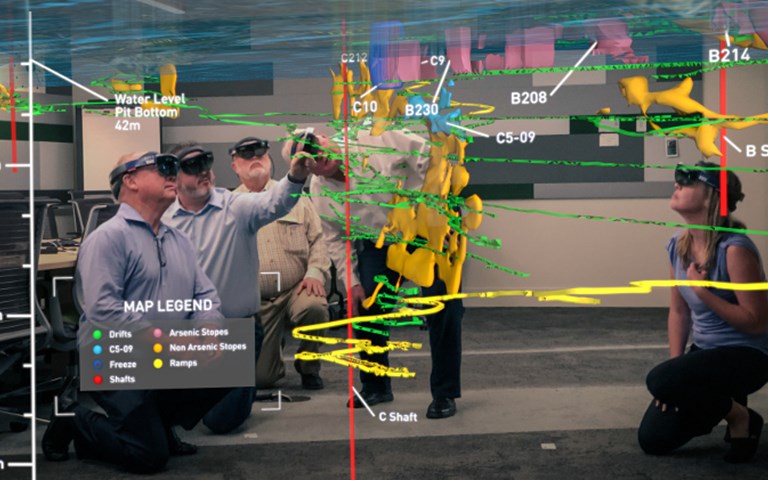

The government uses BGC Engineering’s augmented reality software for community consultation for the Giant Mine Remediation Project

December 19, 2018

BGC Engineering's Ada augmented reality software transforms complex engineering data and plans into 3D models that can be viewed through Microsoft HoloLens goggles. Courtesy of BGC Engineering

This is NOT A PAYWALL To access CIM Magazine, please create a free account

(Note that by creating an account you are not signing up for a CIM membership.)

If you are a CIM member or have already signed up, click here to log in

If you already have a CIM account, please enter your username (often your email) and your password.

If this is your first time here, you can create a free account

More Technology

The automation revolution

There is no doubt the future of mining is automation. But what does that look like, and how will we get there?

The future of flotation

Buoyed by pressure to cut costs and improve recovery, new flotation technologies are on the rise