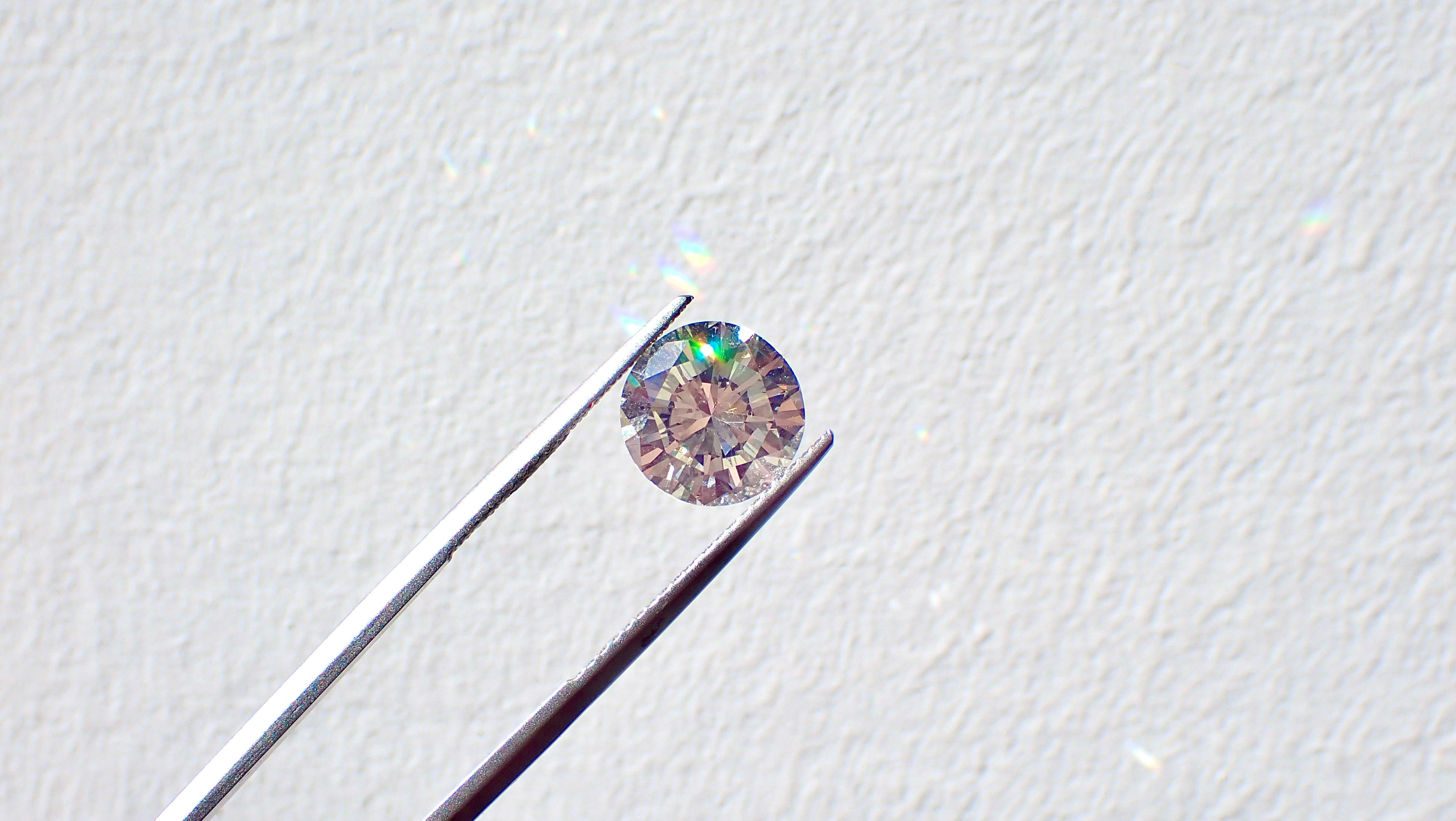

Newmont is selling its Porcupine complex, which is located in and around Timmins, Ontario and has produced over 67 million ounces of gold since 1910. Courtesy of Newmont.

Welcome back to your weekly mining news recap, where we catch you up on some of the news you may have missed. This week’s headlines include plans to construct Canada’s first advanced silicon anode manufacturing facility, Canada’s investment in Foran Mining, and E3 Lithium producing battery-grade material from Leduc brines.

Newmont plans to sell its Porcupine gold operation in Ontario to Discovery Silver for up to US$425 million, completing its plan to divest all its “non-core” assets, as reported by Mining Weekly. The deal, expected to close in the first half of this year, will contribute to total proceeds for Newmont of US$4.3 billion from the sales of its non-core assets and investments. The Porcupine complex includes the Hoyle Pond and Pamour mine properties, the closed Dome mine property and a milling facility in Timmins, as well as the Borden underground mining operation located near Chapleau.

An agreement was signed on Jan. 28 between Ontario and Aroland First Nation to boost infrastructure development in northern Ontario, which is a significant step forward for mining development in the Ring of Fire region as it is the first time there have been agreements in place to build roads along the entire route. The agreement, which will see Ontario invest over $90 million, includes upgrades to Anaconda and Painter Lake roads, which are vital for accessing the Ring of Fire region, and investments in energy transmission lines.

U.S. President Trump’s threat of 25 per cent tariffs on Canadian imports, which could be implemented as early as tomorrow, are weighing heavily on Canadian industries. Cameco is gearing up to challenge potential U.S. tariffs on Canadian uranium again, as reported by The Globe and Mail. In 2018, the company successfully convinced the Trump administration that tariffs on imports of Canadian uranium would hurt U.S. consumers, as the U.S. relies on Canada for 30 per cent of its uranium needs. At the time, the U.S. was considering imposing tariffs on uranium imports as it did for imports on Canadian aluminum and steel.

Meanwhile, Canada’s steel industry is poised to accelerate shipments to the U.S. to maximize revenue before any tariffs are imposed, as reported by The Globe and Mail. The Canadian steel sector, heavily reliant on U.S. exports, was hit hard by similar tariffs in 2018. Steel producers are contemplating adjusting their product mixes and pausing investments to minimize financial damage. If the U.S. moves forward with its threat, the federal government plans to counter with retaliatory tariffs that would impact about $37 billion of U.S. imports, and potentially more to follow.

Canada is working to strengthen its critical minerals supply chains through initiatives like the Canadian Critical Minerals Strategy (CCMS), which aims to increase domestic production and reduce dependence on foreign sources, as reported by Graham Chandler for the February issue of CIM Magazine. Meanwhile, companies such as Rio Tinto and Teck Resources are driving initiatives to boost the North American supply of critical minerals such as gallium and germanium, reducing reliance on China. While progress is being made to strengthen the domestic supply chains, challenges persist, including financing, necessary infrastructure and uncertain U.S.-Canadian relations.

NEO Battery Materials announced that it will build Canada’s first advanced silicon anode manufacturing facility in Windsor, Ontario, investing up to $120 million in the plant, as reported by Mining.com. The company has leased eight acres of land at the Windsor Airport for the facility. NEO aims to construct a commercial plant that would eventually produce 5,000 tons of silicon anodes per year for use in lithium-ion batteries for electric vehicles, electronics and energy storage systems.

The Canadian government announced a $41 million investment in Foran Mining Corporation through its Strategic Innovation Fund on Jan. 28. The investment aims to support Foran’s plans to adopt clean technologies at its McIlvenna Bay copper and zinc project in Saskatchewan, such as acquiring a battery-electric vehicle fleet, implementing a ventilation-on-demand and heat recovery system, developing a water recycling system, and incorporating a pyrite removal system at its tailings facility. Foran intends McIlvenna Bay to be the first carbon-neutral copper and zinc mine in Canada.

E3 Lithium shared that it has successfully produced battery-quality lithium carbonate from brines found in Alberta’s Leduc aquifer using demonstration-scale equipment at its lab in Calgary. The process mirrored conditions planned for the company’s full-scale lithium brine demonstration facility in Calgary, which it said in an October 2024 update would be operational by the middle of this year.

ICMM and the International Network for Acid Prevention (INAP) have developed a new resource to help mining companies prevent and reduce water pollution that results from acid rock drainage (ARD) and metal leaching (ML). The tool is designed to help companies with the implementation of INAP’s “Global Acid Rock Drainage (GARD) Guide” and provides a practical, accessible framework for non-specialists to prevent and manage ARD/ML risks. It offers a comprehensive summary of ARD/ML prevention strategies, tailored to specific stages of mining operations from exploration to post-closure.

Victoria Yehl and James Whyte playfully debunk myths about the term “qualified person” (QP) in the December/January issue of CIM Magazine, emphasizing that a QP is not a title or designation, but rather a concept. This designation identifies the professional taking responsibility for specific public disclosures. To be a QP, one must meet education, experience and professional registration requirements. While a P.Geo. or P.Eng. can act as a QP, the role is distinct from holding a licence.

The Active Allies program is a six-week course designed by Jocelyn Peltier-Huntley, a professional mechanical engineer and EDI expert, to help mining professionals develop allyship skills and improve their understanding of equity, diversity and inclusion (EDI), as reported in the December/January issue of CIM Magazine. The new course focuses on practical skills, such as active listening and being an engaged bystander, while examining challenges that underrepresented groups in the mining industry face. Through online modules and group discussions, participants can gain confidence in discussing EDI topics and creating more inclusive workplaces.

That’s all for this week. If you’ve got feedback, you can always reach us at editor@cim.org. If you’ve got something to add, why not join the conversation on our Facebook, Twitter, LinkedIn or Instagram pages?