Concrete works at Media Luna’s flotation plant during construction of the mine’s surface infrastructure. Courtesy of Torex Gold

This was one of our favourite stories of the year. To see the full list, check out our Editors' Picks 2025.

So far, 2025 has been a pivotal year for Torex Gold. With the successful production of the first copper concentrate from its Media Luna underground mine in Mexico at the end of March, followed by commercial production beginning in May, Torex has transitioned from Mexico’s largest gold producer to also being a major copper producer.

“It was a huge milestone for us,” said Dave Stefanuto, executive vice-president, technical services and capital projects at Torex. “We are going to be producing significant copper with Media Luna—somewhere in the range of 45 to 50 million pounds of copper per year.”

Media Luna represents the next phase in the long-term vision for Torex’s broader Morelos property, a 29,000-hectare property in Mexico’s Guerrero gold belt, approximately 180 kilometres southwest of Mexico City. The Morelos property includes the El Limón Guajes (ELG) mine complex on the north side of the Balsas River, which includes an operating underground mine, processing plant and related infrastructure, as well as open-pit mining operations that have now reached the end of their mining life, having previously anchored production since commercial operation began in March 2016.

On the south side of the Balsas River, approximately seven kilometres south of the ELG mine complex, the company has been focusing on exploring and developing Media Luna. In 2022, it released a technical feasibility study that integrated Media Luna into the overall development plan at Morelos.

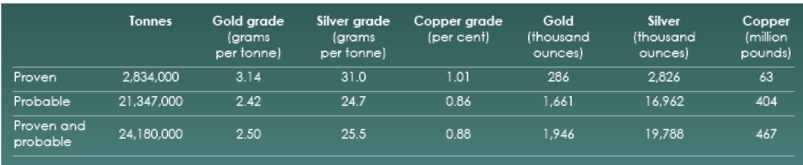

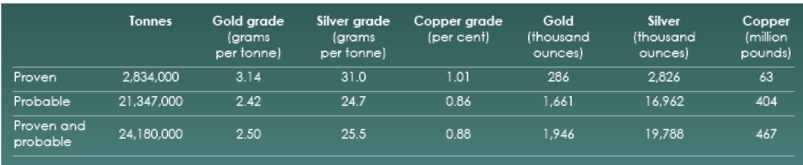

As of Dec. 31, 2024, the proven and probable reserves at Media Luna totalled 24,180,000 tonnes containing 1,946,000 ounces of gold grading 2.5 grams per tonne, 19,788,000 ounces of silver grading 25.5 grams per tonne and 467 million pounds of copper grading 0.88 per cent. The life of mine is to at least 2033, but Torex is hoping to extend it with more exploration at the Morelos property.

Mineral reserves for Media Luna as of Dec. 31, 2024. Source: Torex Gold

Mineral reserves for Media Luna as of Dec. 31, 2024. Source: Torex Gold

Bringing any major mine into production is always challenging and Media Luna was no exception. The project faced its share of headwinds, including global supply chain disruptions, hurricane-related equipment delays and the impact of a strengthening Mexican peso on local costs.

“[Those challenges] caused some cost pressures and a slight extension to our project period into Q1 of this year,” said Stefanuto. “But other than that, we’re very much aligned within the margin of error of the original US$875 million budget outlined within the feasibility study.”

A strong workforce

For Stefanuto, the strength of the Media Luna build has been the team behind it.

During construction, Torex continued operating ELG’s open pits; they are expected to cease production in the third quarter of 2025. The plan was to gradually shift the open-pit workforce to the entirely underground Media Luna mine. This was both a challenge in location and mining method for its employees.

“That’s an area where we saw some real risk,” said Stefanuto. “We weren’t sure how the transition would work out—how do you keep mining the open pit while training those same employees to take over the new operation?”

To mitigate those risks, Torex began early planning of how the Media Luna project would eventually transition from development to operations, embedding operational readiness into the project at the feasibility phase and progressing workforce planning in step with Media Luna’s construction.

By the time Media Luna’s primary assets were ready to produce first copper concentrate in March of this year, 200 workers had successfully transitioned from open-pit to underground roles. Another 160 were recruited, along with 110 employees to run the new copper processing facilities.

“It all came together,” said Stefanuto. “As soon as we constructed the assets, we had a qualified workforce ready to ramp them up and start operating.”

To support the workforce transition, Torex also partnered with Asesorías Mineras Integrales (AMI), a local firm called INMIBE and Sudbury-based NORCAT to support the vast training requirements required for employees to operate safely and effectively in the underground environment.

“It was really a collaboration of our human resources, safety, training and operational teams and external partners that led to the successful transition of our employees,” Stefanuto added.

Designed for battery-electric

Instead of handing over the entire scope to a single engineering, procurement and construction management provider, Torex assembled a group of specialized companies.

Stantec designed the underground mine, material handling systems and infrastructure, while M3 Engineering designed the surface production facilities and surface infrastructure as well as upgrades to existing facilities and overall design coordination. Promet101 Consulting did the process engineering design for the flotation plant and overall processing facilities; Paterson & Cooke designed the paste plant; and BQE Water oversaw the process engineering for the water treatment plant.

From day one, Torex designed Media Luna to support a fleet of battery-electric vehicles (BEVs), playing to the vehicles’ strengths while minimizing their limitations. “Given we were designing a new underground mine, this was the perfect opportunity to design that mine specifically for the BEV equipment,” said Stefanuto. “This is where a lot of other companies fail—they take an existing mine that has not been designed properly for BEV equipment, and they try and force the square peg into the round hole.”

One of the most critical design choices was orienting the mine layout to take advantage of gravity flow.

“All of our ore is fed through ore passes on levels or transfer stations, down to a material handling system and conveyed out at the bottom of the mine,” explained Stefanuto.

This design choice meant BEV loaders and trucks can operate on a single level without the need to travel up and down long ramps, which avoids battery drainage.

Ore from Media Luna is transported to the processing plant on the north side of the Balsas River via an underground conveyor that runs through the seven-kilometre-long Guajes Tunnel. Courtesy of Torex Gold

Ore from Media Luna is transported to the processing plant on the north side of the Balsas River via an underground conveyor that runs through the seven-kilometre-long Guajes Tunnel. Courtesy of Torex Gold

Building the mine around this BEV concept also allowed Torex to rethink other systems from the onset, including ventilation. Unlike diesel equipment, BEVs produce no exhaust emissions, which allowed Torex to design a more efficient and smaller-scale ventilation system for Media Luna that helped to offset some of the higher capital costs associated with a BEV fleet.

The shift to BEVs also supports Torex’s broader environmental goals, which include achieving a 10 per cent absolute reduction in the company’s Scope 1 and 2 greenhouse gas emissions by 2030, compared to its 2021 levels.

But the move to BEVs is not only about hitting emissions targets. “One of the key benefits of a BEV fleet is a cleaner and healthier underground working environment,” said Stefanuto.

There are operational advantages, too. Electric vehicles deliver more torque and higher capacity, explained Stefanuto, making loading and digging more efficient.

“Once we started looking at all these different things, we just saw more net benefits of having a BEV fleet versus going with a traditional diesel one,” said Stefanuto.

Right partners, right job

To build out its electric fleet, Torex avoided the one-size-fits-all approach. Instead, it divided the fleet into three categories: primary production (scoops, trucks, jumbo drills), secondary support (scissor lifts, emulsion loaders) and tertiary equipment (personnel and light-duty vehicles).

“There isn’t one vendor that you can go to as a one-stop shop that can provide that full suite of equipment,” said Stefanuto. “We really wanted the best out of each of those categories, and so that’s how we structured our [request for proposal] and went to the market.”

Sandvik was chosen for the primary production fleet, supplying 11 Toro LH518iB BEV loaders and four DD422iE twin-boom battery-electric jumbos. MacLean Engineering provided 24 pieces of battery-electric secondary support equipment—including explosives chargers, elevated work platforms, graders and material transporters—while Rokion delivered seven personnel carriers, 20 light-duty vehicles and a forklift.

“[This set-up] avoids competition between vendors on-site,” said Stefanuto. “It allowed us to engage three vendors in a more cooperative way to optimize our overall fleet requirements and productivity, both from a maintenance and operations perspective.”

In total, Torex operates 67 BEVs at Media Luna, making it the largest battery-electric fleet in Latin America. The company also runs a mix of cable-electric and diesel equipment for added flexibility, primarily for development. The cable-electric fleet includes five Sandvik longhole drills, a TRB Rhino 100 mobile raise borer, five Sandvik rock bolters and two Sandvik cable bolters. The diesel vehicles include three Sandvik LHDs, three Sandvik haul trucks, a MacLean shotcrete sprayer and a Sandvik blockholer.

Final touches and next phases

Media Luna is now in commercial production, with 98 per cent of its construction completed and only a few final pieces remaining.

Torex is in the last stages of commissioning its paste backfill plant, which is expected to begin production in the third quarter. The facility is critical to supporting the mine’s ramp-up to its full production capacity.

“After that, it’s really about optimizing mine planning and sequencing to get us to 7,500 tonnes per day by mid-2026, about six months earlier than in our feasibility study,” said Stefanuto.

Some of the Torex Gold executive team in front of Media Luna’s first copper concentrate production. Left to right: Dave Stefanuto, executive vice-president, technical services and capital projects; Jody Kuzenko, president and CEO; Faysal Rodriguez, senior vice-president, Mexico; and Andrew Snowden, chief financial officer. Courtesy of Torex Gold

Some of the Torex Gold executive team in front of Media Luna’s first copper concentrate production. Left to right: Dave Stefanuto, executive vice-president, technical services and capital projects; Jody Kuzenko, president and CEO; Faysal Rodriguez, senior vice-president, Mexico; and Andrew Snowden, chief financial officer. Courtesy of Torex Gold

As Media Luna is brought into production, exploration and development across the Morelos property continues.

“Only about 25 per cent of the Morelos property has been explored so far, and we’ve already identified several promising targets that we’re actively pursuing,” said Stefanuto.

In 2024, the company released a maiden resource for the EPO deposit, located just one kilometre north of Media Luna. It hosts a probable reserve of 5,029,000 tonnes at an average gold equivalent grade of 4.83 grams per tonne for a total of 781,000 ounces gold equivalent.

“The idea is to take advantage of the material handling infrastructure we built for Media Luna to access EPO,” Stefanuto explained. “We can develop nearby deposits like EPO very economically and without spending extra money on infrastructure and assets.”

Torex is also actively advancing the idea of Media Luna East and Media Luna West projects, which hold strong potential to further extend the life of the operation.

“The Media Luna project itself is very significant because it extends our existing operations’ mine life by 10 years,” said Stefanuto. “We designed and constructed it thinking about the long-term support of the Morelos property for the next 20 to 30 years.”