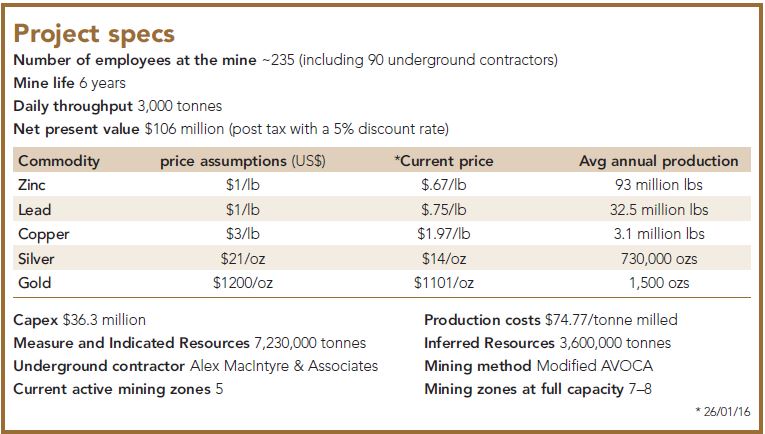

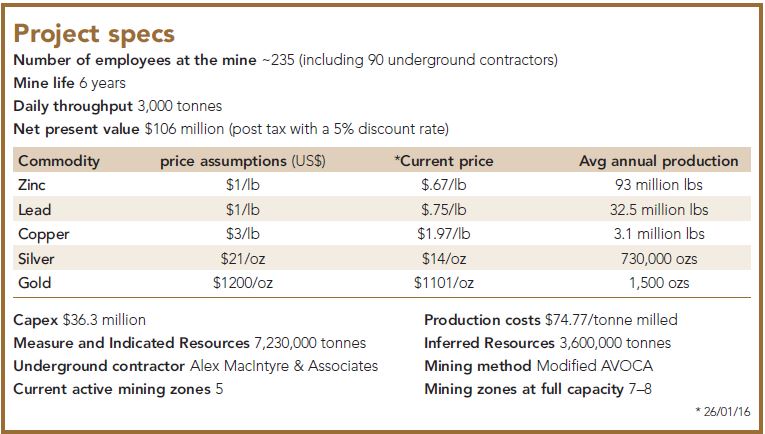

Trevali inherited extensive underground workings at the Caribou mine and has added another 3.5 kilometres of underground development. Courtesy of Trevali Mining

The timing of commercial production at Trevali Mining’s Caribou zinc mine, just as global supply has tightened, could give the project in northern New Brunswick a welcome boost.

The underground zinc-lead-silver-copper-gold mine has stalled and exchanged hands several times over the years, but Vancouver-based Trevali expects it will succeed this time due to the price and market fundamentals of zinc, the very cause of the mine’s demise under its previous owners. Although the commodity sat at around US$0.67/lb in mid-January, mine closures and stockpile depletions are expected to boost the commodity in short order. “The thesis for zinc is that it could move pretty fast as these closures and these shortages in the warehouses manifest,” said Steve Stakiw, vice-president of investor relations and communications.

But that is not all that has seemed to work out for the company. When it acquired the mine and mill complex from Maple Minerals in November 2012, it came with a lot of the infrastructure already in place. Blue Note Mining, the last company to have operated the mine, had developed the property in the mid-2000s and mined the deposit for just over a year before it was forced into receivership in late 2008 because of low commodity prices. It had mined about 500,000 tonnes. “We think we got a pretty good value,” said Stakiw, “given the amount of capital that had been put into that asset, both underground and into the mill complex, was extensive.”

The processing plant has a nameplate capacity of 3,000 tonnes per day. Courtesy of Trevali Mining

The processing plant has a nameplate capacity of 3,000 tonnes per day. Courtesy of Trevali MiningThe ugly duckling

The Caribou mine was more of an afterthought for Trevali when it made the acquisition. What originally caught the company’s eye about the property was the mill. In early 2011, Trevali added Stratmat and Halfmile to its suite of projects, both of which are also located in the Bathurst area of New Brunswick. Trevali began conducting trial mining at Halfmile in 2012, but the mine did not have its own processing facility. So in November 2012, the company purchased the Caribou mine and mill complex for a market value at the time of about $24 million.

Blue Note invested about $100 million during the time it owned the property to overhaul and modernize the processing plant and mine infrastructure. The mine originally began production from an open pit in 1970 under the Anaconda Minerals Company. This had included roughly 13 kilometres of underground development already complete, which Stakiw estimated as being worth $50 to $60 million. “It certainly made our job a lot easier,” he said. Since it acquired the mine, Trevali has invested around $50 million and to date has added 3.5 km of its own underground development.

Since the mine had sat idle since 2008, the existing underground tunnels needed to be refurbished, which Trevali started in September 2014. “In general, 95 per cent of the tunnels were in good condition,” said Barbara Rose, Caribou’s chief mining engineer. But tunnels that intersected with the two major fault lines in the ore body had experienced some failures. So Trevali applied shotcrete to those tunnels in addition to the bolts and wire mesh in place. At this point, all tunnels tied to immediate production have been refurbished.

By December, Trevali had ramped up to about 2,000 tonnes per day of production. During mine commissioning, Alex MacIntyre & Associates mining contractors are doing the underground work. “We wanted to financially de-risk the project during commissioning,” explained Trevali president Mark Cruise. By starting to mine with a fully trained and skilled workforce that came with its own fleet of mine equipment, Trevali was able to reduce the initial capital and training required. Once the mine reaches commercial production in the first quarter of 2016, the plan is for it to become fully owner-operated by mid-2016. At that point, Trevali will run its own fleet, which will include five scoop trams and seven 45-tonne underground haul trucks.

Trevali is using a modified version of an AVOCA longitudinal longhole retreat mining method at Caribou. According to Rose, miners typically have access to both sides of the mining front when employing the AVOCA method, blasting and mucking on one side while backfilling on the other. But because Caribou does not have access to both ends, the underground miners are mucking on the same end that they are drilling, blasting and backfilling from. “The previous operators had run with a modified AVOCA method and so we just continued with that mining method,” explained Rose. “We’re turning around stopes in about 28 to 30 days.”

Mining at Caribou first began from an open pit in 1970. Tom DiNardo

Mining at Caribou first began from an open pit in 1970. Tom DiNardoFine grinding

Because of the fine-grain nature of the ore, Blue Note installed three IsaMills in the Caribou milling complex in 2007. Cruise said he believes it was the first installation of the technology in North America.

The IsaMill is a horizontal, high-speed stirred mill, with a high-power intensity of up to 300 kilowatts per cubic metre (kW/m3) (a ball mill usually runs at less than 40 kW/m3). This allows the IsaMill to process fine particles at a high throughput. It consists of eight rubber-lined discs to grind the feed slurry, which passes through holes in the discs. After the eight discs, the product reaches a separator. The particles that have been reduced to the correct size move on while those that are still too large recirculate to the slurry feed for another round of grinding.

“It’s the key to unlocking the metallurgy and to boosting your recoveries given the fine-grain nature of the ore in the deposit,” said Stakiw. And when it comes to ultra-fine grinding mills, there is not much competition, said Cruise. “The largest zinc mines on the planet use [IsaMills],” he explained.

In order to get a better handle on technology, Caribou mill workers traveled to the McArthur River zinc mine in Australia last February to learn the ins and outs of the IsaMill in what Cruise described as a “master’s course.” In addition, Glencore, which owns and markets the IsaMill technology, was able to provide an on-site technical expert to assist Trevali in starting with commissioning. The company has also added a former MacArthur River employee as its IsaMill operations specialist to optimize the stirred mills at Caribou for grind size and efficiency.

As for the ramp up, Cruise said it went pretty smoothly. “The first month we were fighting it a bit but that’s pretty standard as the guys get familiar with it,” he said. Previously, mill operators needed three IsaMills to effectively grind down the zinc, but Trevali has gotten the same grind with two. “Obviously that’s a lot more efficient and cost effective on media, power consumption and all that stuff,” said Cruise. Additionally, it allows the Caribou mill to use the third mill as a backup during scheduled monthly maintenance, reducing production interruptions.

In addition to the IsaMills, Trevali purchased a new SAG mill and refurbished the two ball mills for its 3,000 tonne-per-day processing plant. Once the ore is fully ground, it goes through the flotation circuit and the concentrate is then trucked a half hour north of Bathurst to the port of Belledune, New Brunswick. Trevali has an offtake agreement with Glencore for all of the zinc and lead concentrate produced.

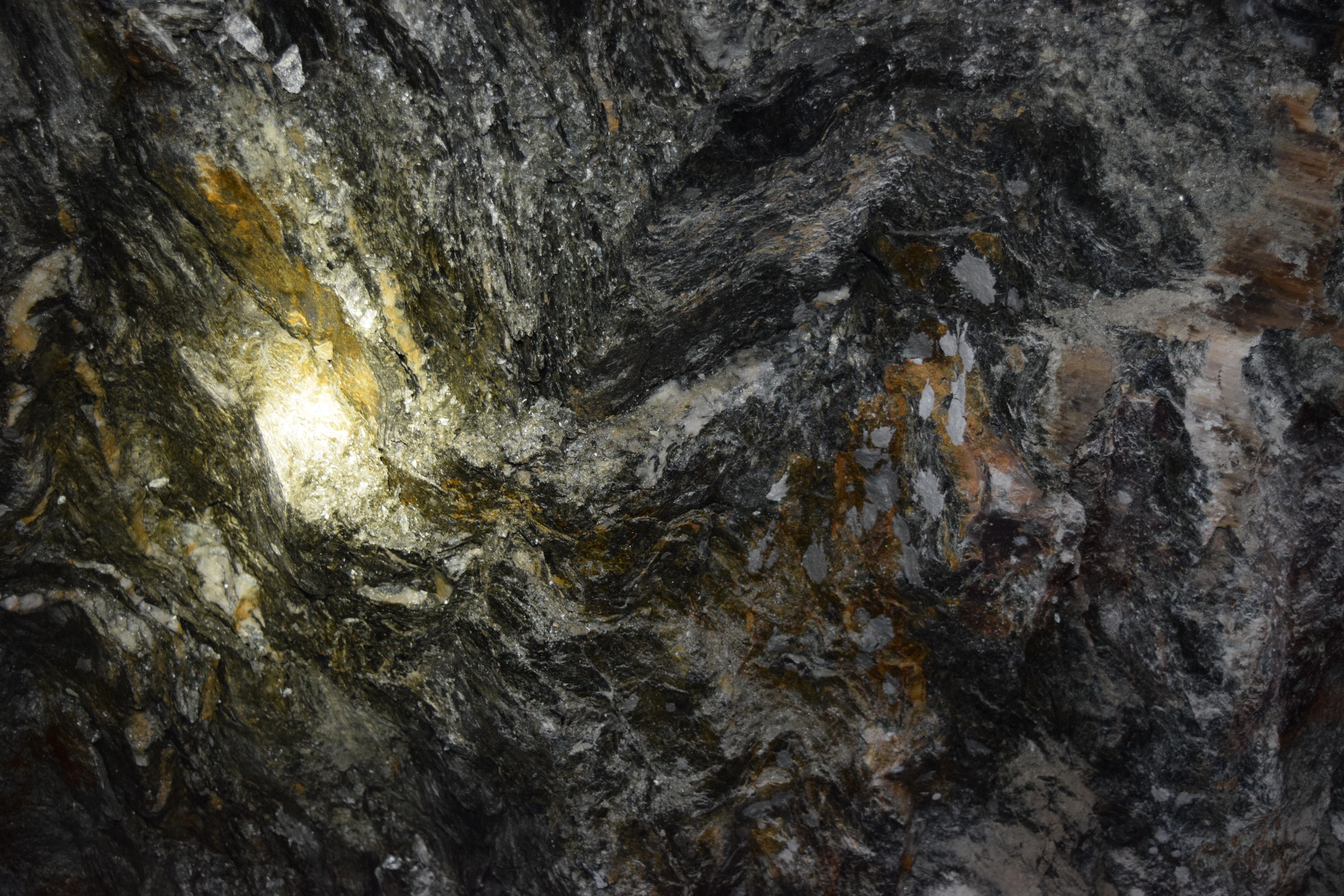

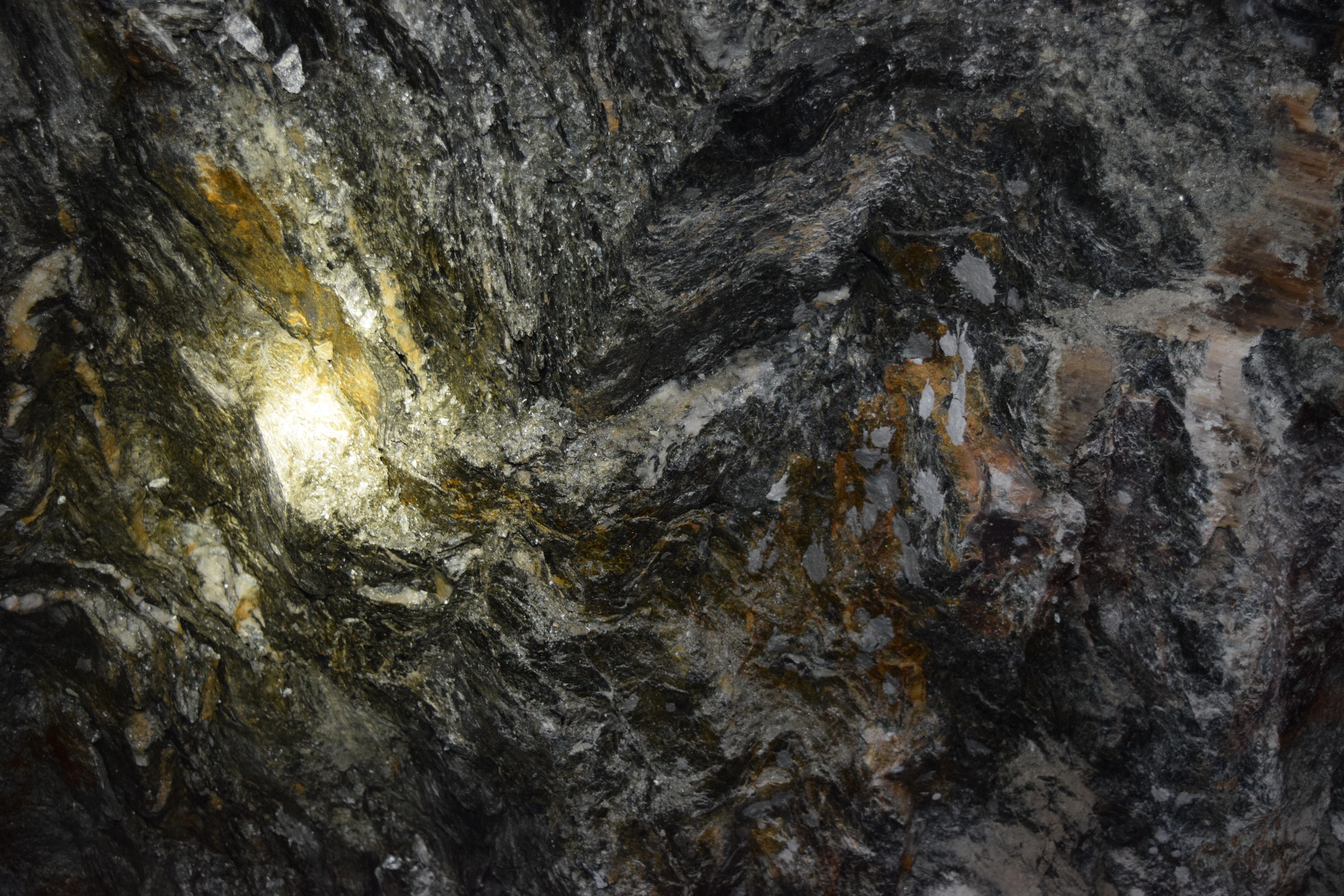

The Caribou deposit is volcanic-sediment-hosted massive sulphide. Tom DiNardo

The Caribou deposit is volcanic-sediment-hosted massive sulphide. Tom DiNardo The Caribou deposit remains open at depth and drilling has found massive sulphides below the currently defined resource. Tom DiNardo

The Caribou deposit remains open at depth and drilling has found massive sulphides below the currently defined resource. Tom DiNardoPrice and production in zinc

Current wisdom says that zinc is one of the few commodities that will soon rebound positively. As of mid-January, it is down almost half a dollar from US$1.1/lb where it stood last April. Stakiw points to the large amount of zinc that has been stockpiled in recent years to explain the drop. “Ultimately we need to see inventories draw down because we’re still sitting with high inventories, but they are coming down fairly rapidly,” he said. “The daily drawdown rates have been increasing from 1,000-2,000 tonnes a day from early last year to 3,000-4,000 tonnes a day near year-end 2015.”

There are also a couple of big mine closures, the impacts of which are only now starting to be felt, according to Stakiw. MMG’s Century mine in Australia, for example, delivered its final shipment of zinc concentrate in mid-December. And the Glencore cutbacks announced in the beginning of October means that it will scale down approximately a third of its global zinc production, he said.

“Starting in the first quarter of 2016, we expect to see a lot of the concentrates that are normally delivered into warehouses to decrease , so drawdowns should start to increase because you’re not getting the restock to balance or offset those drawdowns,” said Stakiw. This will ultimately lead to a drive in price.

The mine is employing contract miners as it trains local workers. Courtesy of Trevali Mining

The mine is employing contract miners as it trains local workers. Courtesy of Trevali MiningEmployment opportunities

Like many mines in Canada, Trevali has an Impacts and Benefits Agreement (IBA) with the local First Nations community. In the case of Caribou, it signed its IBA with nine Mi’gmag bands in 2011.

The main highlight of the IBA is the opportunity to employ up to 20 per cent of the workforce with members of those First Nations. But more than the mere fact of employment, for Terry Richardson, Mi’gmag benefits manager at Trevali and a member of one of the nine bands himself, it is experience that will end up paying dividends for First Nations employees in the future. “You’ve got people in careers that will probably never come back to the band looking for employment because they can go work elsewhere within the mining industry, so that’s huge for us,” said Richardson.

Caribou is not quite at 20 per cent employment just yet, though. “We’re floating around 14 to 15 per cent, but we are getting there,” said Richardson. Nevertheless, this feels like a step forward for the local First Nations community. When Xstrata Zinc’s nearby Brunswick mine closed in 2013, not one of the employees working at the mine was a member of a First Nations, according to Richardson. “It’s ironic and it’s unfortunate, but at least now we’re seeing more involvement,” he said.

In order to boost the ranks of First Nations employees at the mine, Trevali committed to a training-to-employment program as part of their IBA, in partnership with the Aboriginal Workforce Development Initiative and the New Brunswick Department of Post-Secondary Education. It consists of an underground mining training program, delivered by the New Brunswick Community College in Miramichi, and a mill operator training program, delivered by the Collège communautaire du Nouveau-Brunswick in Bathurst. The training consists of essential skills training as well as instruction on occupational health and safety.

So far, 24 candidates have gone through the underground mining training program. Of those, Richardson estimated that about 19 are still working at the mine. “We had a turnover because obviously mining isn’t for everybody, but if you look at [those numbers], there has probably been around an 80 per cent retention, which is pretty good,” said Richardson. Similarly, about 90 per cent of those who went through the mill training program have stayed on.

The application process includes an interview with Richardson as well as an aptitude test to make sure candidates have nine basic skills to perform the necessary tasks on the job, such as reading, writing, math and the ability to understand blueprints.

The cost of the program, which Richardson estimates at around $6,000 per candidate, is being covered mostly by the province. Trevali does provide a training area on-site for the program to take place.

Overall, Richardson sees Trevali’s relationship with the surrounding community as a resounding achievement. “The success we’ve had with our IBA is something we brag about amongst our Mi’gmag nations,” said Richardson. “We’ve started to say, ‘Look, here’s an example of how a company can come in and work with First Nations and it’s to the benefit of everybody: the company, the First Nation and the community’.”