The approach to the Brucejack project includes a 12-km traverse of the Knipple glacier. All images courtesy of Pretium Resources

Up above the treeline in the mountains of northwestern B.C., Pretium Resources’ Brucejack project promises to add lustre to the province’s mining industry.

Cost overruns in the gold mining industry have become so commonplace that investors are justifiably wary of feasibility estimates. But the Brucejack project in British Columbia is trending in the opposite direction as construction progresses, shedding capital costs amid fiercely competitive conditions for equipment and contractors and favourable currency markets.

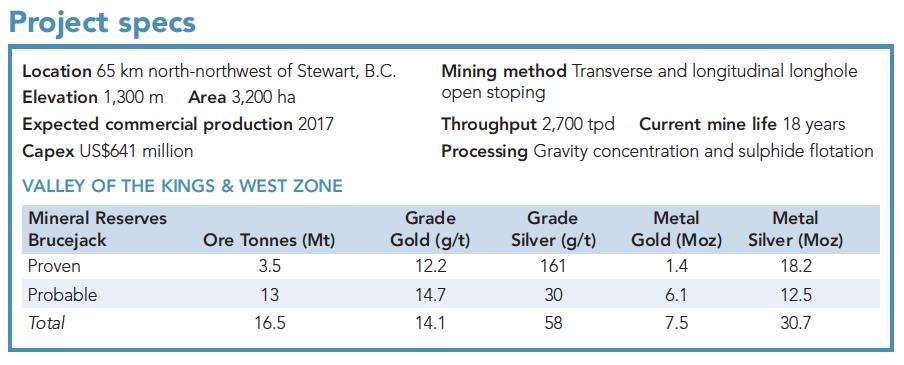

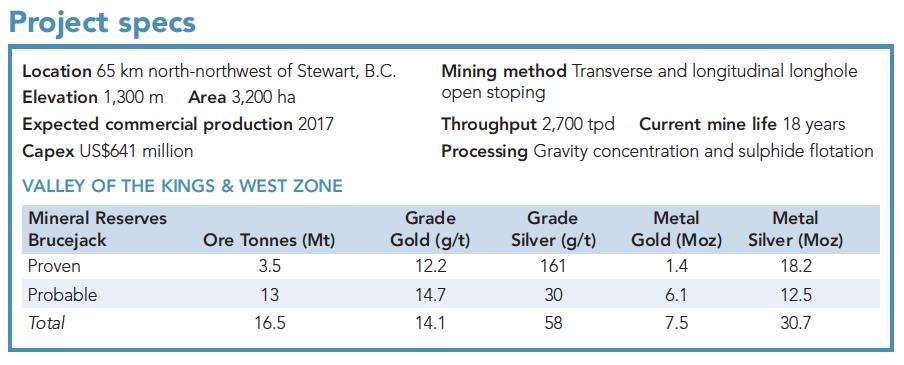

Since Vancouver-based Pretium Resources released a feasibility study for Brucejack in mid-2014, estimated capital costs for the project have dropped 14 per cent to US$641 million. That excludes the US$56 million in working capital set aside for startup in case gold receipts are delayed. The portion allocated to the underground mine fell 33 per cent to about US$101 million.

It is mostly a matter of timing. “The silver lining for us in this industry downturn is that there are a lot companies and individuals looking for work, so there was a very competitive bid process for the underground contracting job and we were successful in getting good terms from a reputable contractor in Cementation Canada,” said Pretium president Joseph Ovsenek.

And while the feasibility estimate assumed an exchange rate of US$0.92: CAD$1, the value of the Canadian dollar has fallen significantly since. Actual conversions – including hundreds of millions in debt and equity financing – are occurring at or near US$0.75 to the Canadian dollar. The exchange savings amount to roughly US$145 million, offsetting higher costs for environmental monitoring, winter construction and additional man hours.

Filling the funding gap

Pretium is also celebrating a financing milestone in an otherwise brutal market for miners. In early March the company raised the final US$130 million needed to build Brucejack through a public share offering at US$4.58 per share. The offering followed a US$540 million financing consisting of US$350 million in debt, a US$150 million prepayment under a gold-silver stream agreement and a US$40 million private placement of shares. Investors opened their wallets after Brucejack received final permits from the provincial and federal governments in mid-2015.

“It’s really an exciting time,” Ovsenek told CIM Magazine after returning to Vancouver from a site visit at the end of March. “Bulk earthworks are winding up, foundations are going in for the permanent camp and we’ll start constructing our mill building soon. By the middle of next year we’ll start commissioning the mill and expect to achieve commercial production before the end of the year,” he said.

With an average grade of 14.1 grams per tonne (gpt) gold, Brucejack is the highest-grade gold project in development worldwide, considerably higher than the next two in line, Roxgold’s Yaramoko in Burkina Faso (11.8 gpt) and TMAC Resources’ Hope Bay in the Northwest Territories (7.7 gpt). The underground mine is expected run for 18 years, producing 504,000 ounces of gold per year during the first eight years of life and 404,000 ounces per year thereafter at an all-sustaining cash cost of US$446 per ounce with the help of the sale of secondary silver.

A core sample from Brucejack

Pretium has continued infill drilling in response to the variability of the grade

Optimizing the flowsheet

Because the mineralized zones at Brucejack are well-defined and the metallurgy (coarse electrum) lends itself to gravity separation, mining and processing will be relatively straightforward. A decline from a surface portal located near the concentrator will provide access to two deposits: The Valley of the Kings and the West Zone. Ore will be extracted at a rate of 2,700 tonnes per day by longhole open stoping (LHOS) – mostly transverse LHOS – and sent to a crusher at the 1,330-metre level. There will be no ore passes; rather a fleet of LHDs and trucks will transport the material from the various working areas to the crusher through an internal ramp system.

Pretium will backfill the empty stopes with paste fill generated from unclassified mill tailings mixed with sufficient binder. At the western margin of the mine plan where the deposit touches the Brucejack fault, recoveries are expected to fall to about 75 per cent, but this more fractured rock represents only four per cent of the orebody. Development through the Brucejack Fault Zone will be supported using a combination of bolts, welded wire mesh and fibre-reinforced shotcrete.

One challenge Pretium faces is variability between high-grade mineralization (sometimes greater than 1,000 gpt) and the surrounding, lower grade stockwork. The feasibility study input data for the Valley of the Kings includes a total of 218,127 meters of underground and surface drilling. To get a better handle on the grade distribution for mine planning, in 2015 the company launched an underground infill drilling program of over 60,000 meters at 7.5 to 10-metre centres. The aim is to drill off the stopes that will be mined in the first three years.

“Ultimately, we have to start mining to get a real feel for the deposit and there is no shortcut for that,” said Ovsenek. “So in the first year, we will have variability on a short-term basis, but as we mine, the grade will become more predictable.”

A 10,000-tonne bulk sample demonstrated that a gravity and flotation flowsheet is well suited for the varying mineralization and the wide range of feed grades.

According to the flowsheet, a conveyor system will feed the crushed ore to a conventional SAG mill and ball mill at surface. The ore will be ground to 90 microns. The resulting material will pass through a gravity concentrator to extract the free gold and silver. Pretium will be able to recover about 45 per cent of its gold through gravity to produce gold-silver doré bars that can be sold directly to refiners. The remaining rock will be processed in flotation cells, concentrated down to less than 10 per cent of its original mass and shipped to refineries or metal traders. Total gold recoveries are estimated to be 96.7 per cent.

Work on the mill began this spring and will be completed in time for commercial production next year

Navigating the glacier

The Brucejack project is situated within the mountains and glacier-filled valleys of northwestern B.C. To reach the project from the nearest highway, Pretium upgraded a 75-kilometre access road that crosses the Nass Area and traverses the main arm of the receding Knipple glacier for the last 12 kilometres. During the winter, the final section can be groomed using snow cats but in the summer the road is an ice surface. The glacier is constantly moving, freezing and thawing and the resulting crevasses are a hazard to ATVs and people on foot.

To maintain the road and keep it safe – particularly along this section – Pretium hired Tsetsaut Ventures, a contracting company run by the Skii km Lax Ha First Nation who have asserted rights in the area. “You need constant maintenance along the glacier. Tsetsaut does a good job, grading the road, grooming it in the winter and filling in the crevasses,” said Ovsenek. “They are sensitive to potential environmental impacts on the glacier because it means a lot to them.”

Aside from maintaining the access road, Tsetsaut supplies trucks and earthmovers, manages the work camps and provides other services. The First Nations group has been working alongside Pretium since the junior purchased Brucejack and the nearby Snowfield project in 2010 and, by all accounts, the relationship is a respectful one.

The company upgraded a 75-km access road to reach the project.

Extending the mine life

Ovsenek does not hesitate to call Brucejack a “company-maker” and it is easy to understand why. The deposit is a transitional epithermal gold silver occurrence hosted in stockwork veins that were formed when a porphyry system introduced magmatic fluids through conduits to the overlying strata. The potential for finding more gold within this large hydrothermal system is high.

Aside from Proven and Probable Reserves of 16.5 million tonnes grading 14.1 gpt gold, Brucejack contains Resources of 15.3 million ounces of gold in the main Valley of the Kings zone and the smaller West Zone 500 metres to the north. Valley of the Kings is currently defined over 1,200 metres (m) along strike and to a depth of 650 m. The defined reserves only cover approximately 450 m of strike and it is open to the east and west along strike and at depth.

In 2015 Pretium conducted a regional exploration program, including 20,000 metres of drilling, to target porphyry and epithermal-style mineralization to the east of the project area. The program succeeded in extending the strike length of the Valley of the Kings mineralization 1,000 m to the east to what is called the Flow Dome Zone. Intersections included 2,100 gpt gold over 2.05 m, including 8,600 gpt gold over 0.5 m.

“We initially drilled the Flow Dome Zone as a separate target, but we intersected Valley of the Kings-style mineralization,” said Ovsenek. “Our geos are quite confident, looking at the core and the position of the mineralization, that it is an extension of the Valley of the Kings. Once we’re in production, we’ll drive over there underground and set up some drill stations to confirm this theory.”

Meanwhile, Pretium’s Snowfield project immediately to the north, a massive bulk tonnage opportunity with resources of about 26 million ounces of gold and 3 billion pounds of copper, awaits better commodity markets.

“Snowfield could become worth building if the gold price improves and the copper price surges,” said Ovsenek. “At these prices, we are keeping up the environmental baseline work on Snowfield, but our focus is Brucejack.”

Work on the mill began this spring and will be completed in time for commercial production next year

Work on the mill began this spring and will be completed in time for commercial production next year The company upgraded a 75-km access road to reach the project.

The company upgraded a 75-km access road to reach the project.