The processing plant area at the Blackwater mine in May 2023. Courtesy of Artemis Gold

Mines that are looking to decarbonize their operations often focus on the fuel used in their vehicle fleets, but eliminating the use of fossil fuels in mineral processing plants can also help in achieving companies’ net-zero emissions targets.

The mineral processing solutions provider Sedgman took on that electrification challenge in its design and construction of the six million tonne per year plant at Artemis Gold’s Blackwater mine, which is currently under construction in central British Columbia, a jurisdiction with access to affordable, renewable hydroelectricity.

The idea, said Karl Haase, director of engineering at Sedgman, was a collaborative one between his company and Artemis Gold.

“They really had a strong environmental focus,” he explained. “When they were building the [Blackwater] mine and when they went for consultation, it was one of the key things that they really wanted to be on top of—essentially working with us on a mandate for best environmental practices.”

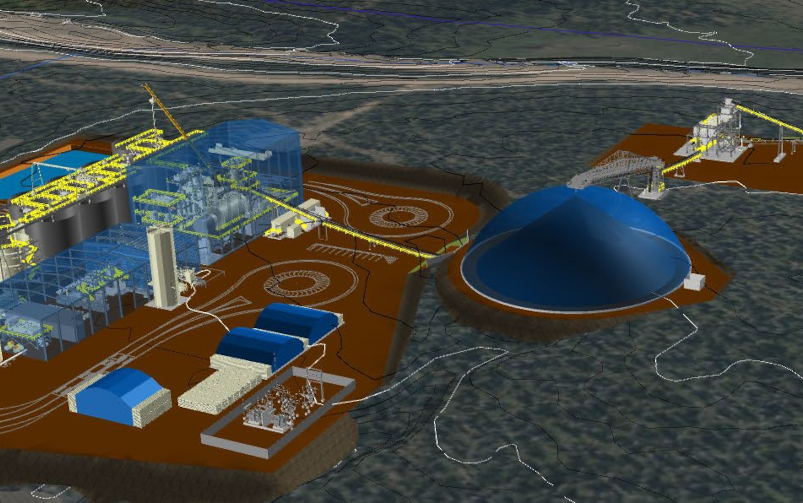

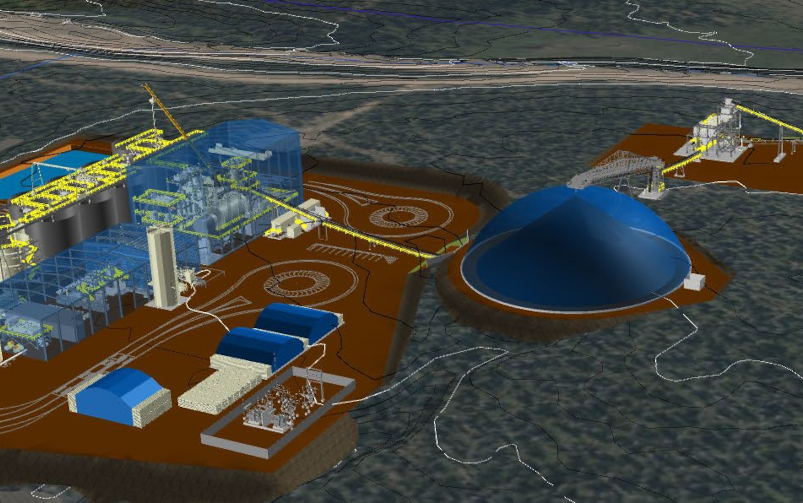

A model of the processing plant under construction at the Blackwater mine. No fossil fuels will be used in any of these buildings or areas. Courtesy of Sedgman

A model of the processing plant under construction at the Blackwater mine. No fossil fuels will be used in any of these buildings or areas. Courtesy of Sedgman

The plant will consist of a three-stage dry crushing circuit, and a 14-megawatt (MW) single-stage ball mill and gravity gold comminution circuit, combined with a carbon-in-leach circuit processing 16,000 tonnes per day. Sedgman’s plant design included electric elution heating, electric kiln and electric smelting, instead of the typical use of natural gas or diesel as a heat source.

Construction began in 2023, and Artemis Gold plans to begin commissioning the plant in the second half of 2024. It is planned to be in use for 22 years.

“Putting [fossil-fuel free] into [the design] mandate was really great for our engineers, because it removed the decision a little bit,” Haase said. “We’re looking at which electric technology [to use], not which technologies in general.”

Challenges of plant electrification

Going all-electric was not straightforward, however. As any cook knows, while heat from the burning of fossil fuels stops as soon as you turn off the burner, electric elements cool down gradually. That, Haase said, presented some operational challenges.

For example, Artemis Gold decided it wanted a prilled sulfur burning system to create the sulfur dioxide to detoxify the reagents used in gold extraction.

“Typically, [sulfur burning] is started on fossil fuels, and then the sulfur will actually be burnt itself,” Haase said. “We had to approach a partner to get a design that would be fully electric for the startup. There has to be a standby electric system to keep the refractory brick hot [at all times], so that it doesn’t crack or cause any damage to the system while you’re not burning sulfur.”

To address this problem, he said, Sedgman designed two separate backup heating systems. But, Haase noted, that meant a lot of heat was being created that was not always needed to burn the sulfur. As a result, Sedgman also created ways to use that excess heat to, for example, fuel steam jackets around the piping to keep the molten sulfur at the proper temperature prior to the sulfur burner, or to heat the water going to the lime silo so its reaction would occur properly. The team also looked at ways to supplement the building’s heating with waste heat from the burner.

Another area that needed special attention was the electric kiln used in carbon regeneration, which needs to reach temperatures of around 700 degrees Celsius. The kiln rotates so that the carbon gets evenly heat treated; however, if the power goes off and rotation ceases, because the electric coils do not instantly cool, the internal vessel could warp as some spots sit on the heating elements and others cool rapidly. This meant that battery backups for rotating components were critical, Haase noted.

But the biggest challenge, he said, was the size of the equipment and the size of the cables needed to power it.

“Typically, diesel-fired elution heating is a very small burner and that system maybe takes up a couple of square metres of floor space. It’s very easy to fit in,” he said.

“With this [electric elution heating] system, it’s three sets of water heaters stacked together with a lot of electric junction boxes—it all has to be low voltage, because you’re basically forcing resistance to create the heat. To create that resistance, everything is done at 600 volts, rather than at a higher voltage,” Haase explained.

“There are 18 electric cables connected in, and they’re quite thick. Getting those [set up] in a sensible way, not restricting access, and then being able to put them into the same junction box was a challenge for both us and our suppliers.”

The electric elution system alone requires 4.2 MW of installed power, and the electric kiln needs another 700 kilowatts, he noted—this is about 15 per cent of the total power at the Blackwater mine plant. “Between those two, having almost five megawatts of low voltage heating is a significant challenge to get engineers on board, and then also make sure that it’s all safe. Low voltage electrical cable is large, harder to install and has safety risks if not done properly—mostly around getting large cables into junction boxes. Fossil fuel systems don’t have these electrical challenges, and are typically smaller and more cost efficient.”

Haase said that power outages are the largest safety concern in electric equipment. “With fossil fuel-based burner management, [if] you cut power, the fuel and heat stops nearly instantly,” he explained. “With electrical induction heaters, the actual elements can stay hot for some time, while other parts that were previously pumping or rotating are now stationary.”

However, he pointed out, the electric elution system should be “a pleasure to operate” compared to a fossil fuel-powered system, because even the best of those systems have some leakage in their ducting, which makes them smelly and dirty. This all-electric installation, he said, will be “amazingly clean” to operate.

Power consumption

The processing plant at the Blackwater mine will consume a lot of power. To supply it, Artemis Gold is building a 140-kilometre grid extension to the site.

Haase’s team is still working on calculating the number of tonnes of CO2 that will not be generated thanks to the cleaner processes at the plant, but the carbon emissions savings are expected to be significant.

Haase advised companies that are considering electrifying a gold processing plant to be aware when budgeting that there will be additional capital expenses upfront compared to plants powered by fossil fuels.

“However, assuming that your power generation is cheaper than the fossil fuels you would buy—which it typically is—you will regain that capital in operating costs,” he said. “How you treat that as an NPV [net present value] is going to be the tricky thing for some junior miners, where they might feel, ‘I’m never going to make that money back’ in terms of project value, NPV or ROI [return on investment]. That’s, unfortunately, where some of these things don’t get pushed forward.”

The biggest thing to remember is that, in this case, affordable, renewable hydroelectricity is available in B.C., he noted. In other locations that do not have a good hydroelectricity base, questions need to be asked before proceeding.

“We also need to look at—where does the power come from, how can we generate that cleaner and how do we get reliable baseload power for these projects in an affordable way?” he observed. “I know there are a lot of projects that are not going to be able to get hydro power. For them, going all electric would sound great, but it’s not really; you’re just pushing the problem further down the line. That’s probably the biggest missing piece: how do we get affordable, renewable, on-site power generation for these facilities?”