Hexagon’s Drill Assist is designed to work like an expert drill operator, using AI to optimize the drilling process at open-pit mines in real time. Courtesy of Hexagon

This was one of our favourite stories of the year. To see the full list, check out our Editors' Picks 2025.

Miners are increasingly under pressure to cut operational costs, boost productivity and reduce risks while meeting the global demand for minerals.

From exploration to drilling and blasting, traditional methods during these stages of the mining cycle often rely on limited data, expert human experience and time-consuming processes.

To tackle the growing pressures, a new generation of companies and research hubs are turning to artificial intelligence (AI) tools to improve decision-making, automate tasks and make better use of existing information. Whether it is finding new deposits, optimizing drill parameters or simulating blast outcomes, these emerging technologies are helping miners work faster, smarter and with greater confidence.

Smarter decision-making

Mineral-X, a research hub at Stanford University, is combining advanced AI algorithms with geoscience to tackle one of the most uncertain stages of mining: exploration.

Traditional exploration relies heavily on deterministic models, where decisions are made based on human interpretations of limited datasets. This approach leaves exploration efforts vulnerable to uncertainty stemming from not having enough reliable data to accurately characterize what lies beneath the surface.

“That deterministic way of thinking is wrong [because] you are very likely to be relying on a wrongly interpreted model of the geology,” said David Zhen Yin, Mineral-X’s co-founder and program director.

Mineral-X’s AI system instead creates visual representations of a wide range of plausible subsurface scenarios by combining stochastic geophysical inversion and computer vision technologies. This approach increases the efficiency and accuracy of exploration, Yin said, because it helps to reduce exploration risks and optimizes decision making.

Mineral-X’s David Zhen Yin presents at the Silicon Valley Minerals Forum. Mineral-X’s Intelligent Prospector creates visual representations of a wide range of plausible subsurface scenarios to increase exploration accuracy and efficiency. Courtesy of David Zhen Yin

Mineral-X’s David Zhen Yin presents at the Silicon Valley Minerals Forum. Mineral-X’s Intelligent Prospector creates visual representations of a wide range of plausible subsurface scenarios to increase exploration accuracy and efficiency. Courtesy of David Zhen Yin

“That’s one major benefit of modern computational science,” added Yin. “You now have a much higher level of computational power that you can evaluate all the possible solutions. You can actually now start to rank them.”

Additionally, Mineral-X’s Intelligent Prospector algorithm doesn’t just model what might work best right now but it also looks ahead. It can predict how today’s drilling decision could impact outcomes in the future.

“You are not just calculating the rewards, for example, from the next upcoming drill hole,” said Yin. “You are going to plan and optimize cumulatively for many drilling steps ahead, over a long-time horizon.”

That kind of forward-looking insight makes the process far more efficient, Yin said, and thanks to modern computing power, these complex calculations can be done quickly too.

This approach also played a key role in the discovery of the Mingomba copper deposit in Zambia.

Mineral-X partnered with KoBold Metals on a research project, developing Intelligent Prospector to guide the exploration of Mingomba. Intelligent Prospector plans optimal sequences of drilling over time while accounting for multiple geological human hypotheses and future decision impacts.

The Mingomba discovery is a high-grade sediment-hosted copper deposit, with rich copper mineralization bounded by deep, hard-to-map faults, making it especially complex, said Yin. Different geologists would have different hypotheses about where these faults might be, and traditional methods would involve drilling based on just one plausible hypothesis. Instead, Intelligent Prospector treated each hypothesis as a different scenario and used AI to plan a sequence of drill holes designed to test and eliminate the least likely ones.

“Each geologist’s hypothesis becomes a computational scenario,” said Yin. “If you think the fault is there, our goal is to tell you it’s not. That’s how you maximize information gain.”

This human-in-the-loop AI system is based on the principle of falsification, popularized by science philosopher Karl Popper, as a core design logic, said Yin. Instead of searching for confirmation, Mineral-X’s AI targets geological uncertainty. It tests hypotheses not to prove them right, but to attempt to disprove them using observed data.

By falsifying the wrong hypotheses using data, it helps geologists refine their models faster and make better-informed drilling decisions. It helped KoBold quickly optimize the drill hole planning on key areas of geological uncertainty, such as fault boundaries, mineralization zone thickness and grade, said Yin, and also saved the company the time and costs that would have otherwise been spent chasing the wrong targets.

Drilling towards productivity

Beyond exploration, AI is making its way into the operational stages such as production drilling.

Hexagon’s Drill Assist, developed by Arizona-based Phoenix Drill Control and acquired by Hexagon in June 2025, is built around an AI technology that optimizes the drilling process at open-pit mines in real time. At its core is an AI algorithm and decision engine that acts like a digital expert operator.

“Drilling is an art,” said Curtis Stacy, commercial director for Hexagon’s autonomous drill solutions. “Drilling a hole is very complicated because the geology changes as you’re drilling. You may start off with a very soft ground type and then enter into a very hard ground type, and then enter into a layer that is highly fractured.”

Drill Assist uses an AI algorithm that can account for all of those different occurrences that may come up and optimize them in real time.

“It’s highly dynamic,” said Stacy. “As you’re drilling, the AI engine is constantly, every 10 milliseconds, monitoring machine feedback and making decisions about whether it’s optimized or needs to adjust.”

Drill Assist is OEM agnostic and can be easily implemented across a mine’s existing fleet, so there is no need to remove or replace the drill’s pre-installed automation system.

But what really sets Hexagon’s Drill Assist apart from other automation systems, said Stacy, is what it does not have. “There are no interfaces or screens that would allow the operator to make any changes at all. The AI optimizer does it all on its own.”

Unlike other systems that still rely on skilled personnel to fine-tune settings and parameters, Drill Assist handles everything in real time, without intervention, to boost a mine’s productivity. This level of autonomy is especially valuable in an industry facing a severe labour shortage, Stacy said. Even when workers are available, he added, it can take about a decade to train a driller to expert level.

“Take any driver, throw them on the drill and they just simply have to press a button to start the drill,” said Stacy. “That’s the advantage of Drill Assist: you can take anyone and teach them how to move from point A to B and they are more productive than your best operator.”

Drill Assist is currently running at three mine sites across the Iron Range and one copper mine site. So far, feedback across all locations has been consistent, with mines experiencing productivity increases of 20 to 30 per cent over their best operators.

“There’s an iron mine in the northern United States that says when [Drill Assist] is utilized, they are 50 per cent more productive,” said Stacy. “We’re doubling their productivity by using this technology that enables them to shut other machines down and drill out patterns faster; it changes their mine planning process and makes the entire mine site more productive.”

Predictive blasting

Open-pit blast designs can often be rushed or based on outdated patterns, with little consideration for what is actually in the ground. The result is inconsistent blast outcomes and costly errors. Watoga Technologies, a Montreal-based startup founded by three McGill University graduates, is aiming to address these challenges with its flagship software, RockHound. The software is designed to automate and improve each step of the blast design by analyzing existing mine data and real-time operational information.

“The key [for blasting] is knowing what is in your ground, what you are blasting and what will be the outcome of that blast,” said Samuel Desjardins, co-founder of Watoga. “But that’s hard to do when you’re racing against the clock to produce fast.”

RockHound starts with a predictive subsurface model, created with machine learning and geostatistical models, that can run in parallel with a mine’s existing operations. It ingests operational and geological data and builds a detailed digital model of the bench.

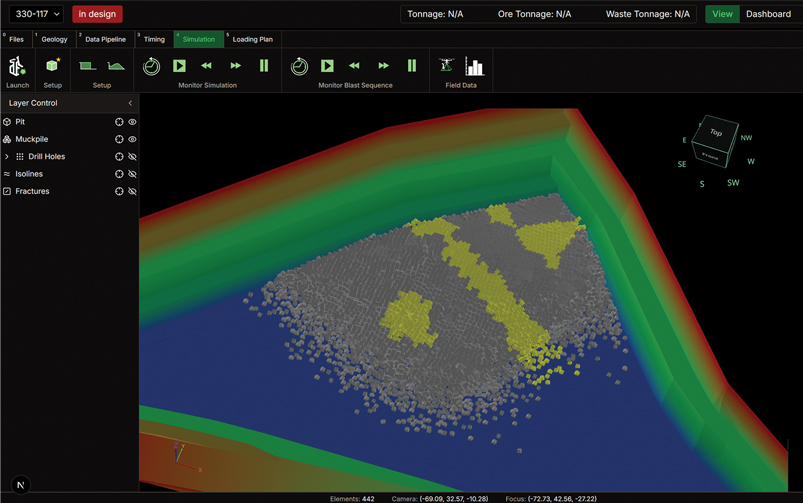

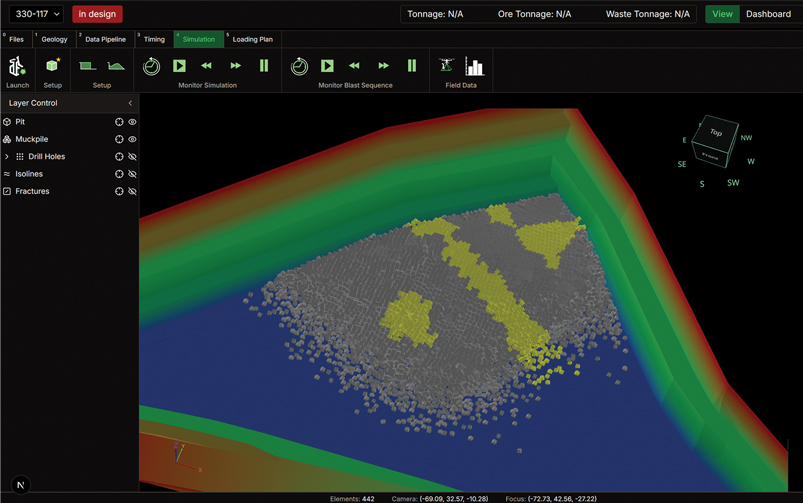

RockHound generates an optimized blast plan based on site-specific conditions and historical performance data, and simulates the blast before detonating. Courtesy of Watoga Technologies

RockHound generates an optimized blast plan based on site-specific conditions and historical performance data, and simulates the blast before detonating. Courtesy of Watoga Technologies

“No one really does predictive subsurface modelling for bench predictions,” said Elliot Forcier-Poirier, another co-founder. “What we do is, as you collect all this operational data, we set up a pipeline that automatically feeds into this subsurface modelling tool and updates your predictions dynamically as soon as you get the data. Then, based on that, we predict a very high-resolution, discretized version of your bench with all these attributes predicted.”

The goals are not only to predict ore grade and location, but also geotechnical data such as fault lines, rock strength and the discrete fracture network (DFN). These inputs are crucial, as they shape how vibrations and fragmentation will propagate during the blast.

“Mines already have a wealth of data,” added Forcier-Poirier. What is missing is the time and tools to use the data more effectively. RockHound’s modelling engine updates predictions in real time as new data becomes available, so engineers are always working from the most current information.

From there, RockHound generates an optimized blast plan based on site-specific conditions and blast performance from the site’s historical data and simulation results. It specifies and optimizes the drill locations, explosive volumes, detonation sequences, burden and spacing.

Before a single blast is made, it simulates the blast outcome, predicting material movement, spatial fragmentation, vibration impact, wall damage and excavation time.

“You want to reconcile your data after, so you want to know how good you are at predicting what’s in your ground and the outcome of the blast,” said Desjardins. “Bad fragmentation will cost money to the mine in maintenance and energy costs.”

The company is looking to publish a case study in the fall and is looking for design partners to expand its offering to meet the needs of open-pit and underground operations.

While the Watoga team sees growing interest in its technology, they recognize that introducing automation into a traditionally cautious industry is no easy task.

“Miners are really risk averse, and the last thing you want is to have plans designed automatically that are not good for some reason,” said Desjardins. “That’s why, throughout the process, an engineer must verify and approve the plan. There might be small details the software didn’t foresee, but the user can make quick modifications and approve it.”

By taking on the heavy lifting of the data analysis, RockHound frees up engineers to focus on valuable on-the-ground tasks, Desjardins added.

“Like most good machine-learning approaches, the goal is to make humans more productive,” said Forcier-Poirier. “Do it faster, do it better and get more value from what you already have.”