ABB Ability Ventilation Optimizer learns from the mine’s operational patterns to provide ventilation on demand. Courtesy of ABB

Ventilation serves multiple purposes in underground mines. It delivers fresh oxygen to workers, dilutes and removes hazardous contaminants and helps to control temperature and humidity in the most extreme conditions. Without an effective ventilation infrastructure and system, miners can be exposed to dangerous concentrations of toxic gases and dust, which can cause severe health risks.

Traditional mine ventilation systems, which often rely on fixed schedules and manual adjustments, struggle to keep pace with the dynamic conditions underground. This not only drives up a mine’s total energy consumption but can also account for a significant portion of operational costs.

Ventilation solution providers are advancing ventilation technologies to meet the demands of modern mining. Each of their innovations, in part, helps enable operators to deliver fresh air deeper underground, while monitoring, controlling and optimizing airflow in real time to ensure that air is delivered exactly where and when it is needed.

Efficient fans

The core infrastructure of any ventilation system is the network of fans that provide and regulate the flow of fresh air underground while removing exhaust gases, heat and dust. Minetek has developed its Raptor series of fans, which includes a primary and secondary fan for underground operations.

The roles of these fans are essential. The primary fan is the backbone of a fan system, explained Jeremy Sutherland, underground mining ventilation manager at Minetek. Sutherland compared the primary fan to the main road from surface to the bottom of the mine. “That’s what the primary fan does. It draws air from the surface all the way to the bottom, and then takes it back out,” he said.

The secondary fan functions more like an off-ramp. “The secondary fan pulls the air off the primary circuit into that working face, pushes it to the end, and then it returns to the primary circuit before heading back to the base,” he said.

In July this year, Minetek launched its Raptor series secondary fan to address a gap the company had identified in the market where existing fan models could not push air far enough into the working face without requiring multiple units.

Minetek launched its Raptor series secondary fan to help push air provided by the primary fan deeper into the mine. Courtesy of Minetek

Minetek launched its Raptor series secondary fan to help push air provided by the primary fan deeper into the mine. Courtesy of Minetek

“Normally, once you get over a certain length in a drive—say, three or four hundred metres—you have to put up another fan to push the air further. We decided to develop a fan that could go the full distance with just one unit,” said Sutherland. The result was a mixed flow fan—a first for secondary ventilation applications—allowing mines to maintain uninterrupted production for much longer stretches.

In the highly competitive underground ventilation market, differentiating one fan from another can be challenging.

“A fan is a motor, it’s an impeller, and it moves air—so what can you do that’s better?” asked Sutherland. “It’s motor efficiencies and airflow efficiencies. Then, when supplying fans and building fans, you need to make them easy for the end user.”

The Raptor series was built with an efficiency-driven design. “Our Raptor series is lighter, it’s shorter and it has less installed kilowatts for the same performance as other fans on the market, making it a lot quicker to install,” said Sutherland. “What that equates to in installation fees is huge in dollar [savings].”

Minetek’s primary fans are direct drive, meaning the motor is integrated into the fan itself. In many competing systems, the motor is external to the fan, requiring the fan to be built on-site—a process that can take up to six months. By contrast, Minetek manufactures and tests its fans in-house before shipping them to the site as complete units. This approach enables rapid deployment.

At a gold mine in Western Australia, Minetek was hired to replace underperforming fans. The company’s pre-assembled units “were installed, commissioned and fully operational in just three and a half days,” Sutherland said, adding that the speed took the market by surprise.

“We don’t do it that quickly every time, but it shows the way that we build our fans, test them at our warehouse and our manufacturing plant first, then when we get to the site, we can be in and out extremely quickly and efficiently,” he said.

Optimizing ventilation

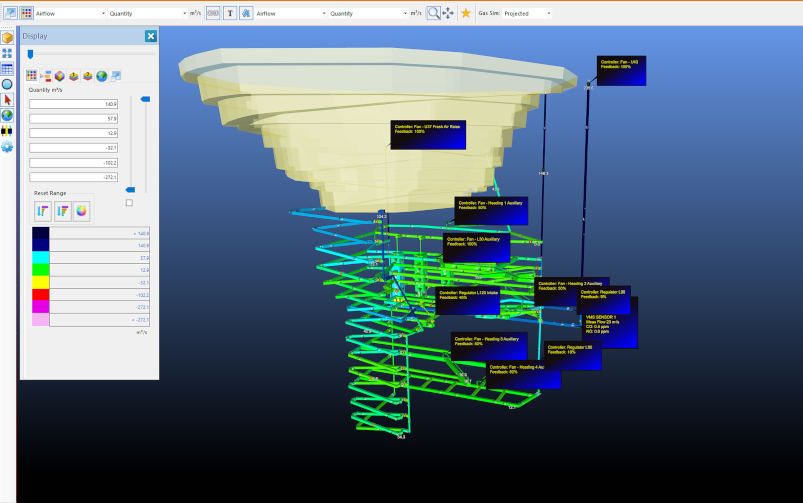

ABB takes a holistic approach to mine ventilation with its ABB Ability Ventilation Optimizer, a complete control solution that integrates ventilation on demand (VOD) functionality.

By combining a tracking and tagging system with environmental and flow sensors, the system is designed to ensure that ventilation is delivered only where and when it is needed. Vehicles and personnel are equipped with transmitters or tags carrying unique IDs, allowing the system to detect their presence and automatically adjust airflow volumes based on pre-programmed requirements.

The system’s capabilities expand further when paired with model-based control, which uses continuous feedback from sensors to dynamically adjust airflow in real time. Data from all sensors, along with fan speed, status and regulator performance, is fed into a central control system. From there, operators, engineers and mine managers can monitor and control the entire network from mobile devices.

Over time, the optimizer learns from the mine’s operational patterns.

“The system learns how to deliver optimized ventilation based on where the people are, where the equipment is, the operating conditions and the production schedules,” said Sachin Jari, general manager of mining for North America at ABB. “You look at what’s going on, and you have control algorithms to provide optimization.”

The result is substantial efficiency gains. According to ABB, dynamically ventilating only active areas can cut energy consumption by 30 to 50 per cent, translating to around US$2 million to US$3 million in annual savings for a typical large mine. Reduced wear on ventilation equipment and improved air quality also contribute to a longer lifespan for the equipment and a safer and healthier working environment.

Jari highlighted openness as a core feature of ABB Ability Ventilation Optimizer. “It’s an open system—we’re not limited to saying you must have this from ABB or that from ABB,” he said. “Our value is really the application knowledge.”

There are three scalable implementation levels. Level 1 provides essential fan, louvre and ventilation door control and monitoring via ABB’s 800xA System, coupled with air quality and airflow sensors to improve safety and reduce energy costs.

Level 2 delivers a full-scale VOD solution, automatically adjusting all controllable ventilation infrastructure to improve air quality.

Lastly, Level 3 adds ABB’s SmartAir Optimizer, using real-time airflow sensor feedback to fine-tune main fan operation for true mine-wide ventilation optimization.

“The three levels are valuable for different mining conditions and investment perspectives,” Jari explained. “Sometimes, people just want a very basic control system—they don’t need an advanced optimization level.”

It’s possible for a customer to scale up from one level to the next, he added.

“This is a fundamental part of the design,” explained Jari. “As you operate and gain more confidence and experience, you can add software capabilities and progress through the different levels.”

Modelling and controlling

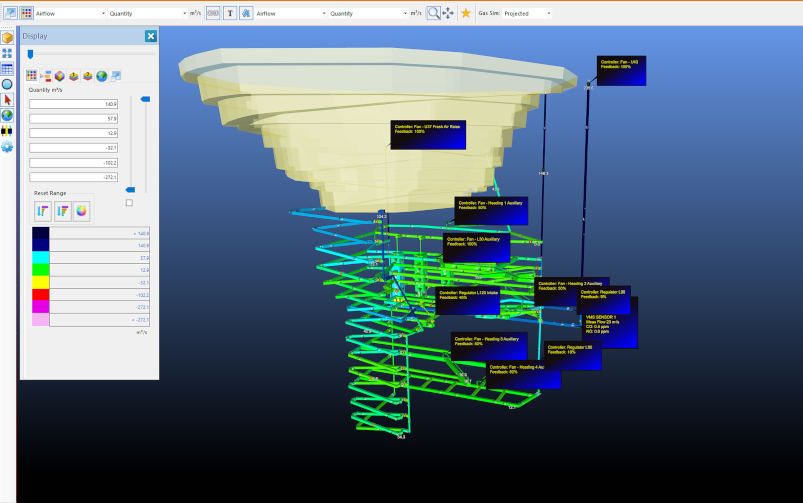

Underground mines are constantly experiencing changing ventilation environments, from airflow shifts to pressure rises and falls, temperature fluctuations and circulation of contaminants. “To understand all of this, there’s no better way than visually,” said Jose Pinedo, sales manager at Ventsim, a Chart Industries company.

Ventsim’s advanced 3D simulation platform, Ventsim Design, models and simulates complex underground conditions, from airflows, pressures, heat, gases and radon to fire scenarios.

“Today, a simulation tool has become something that is essential to every single operating mine, because they need to be able to determine not just what’s happening today, but what’s going to happen in the future,” Pinedo explained.

Ventsim Control is designed to remotely monitor, control and automate airflow in underground mines. Courtesy of Ventsim

Ventsim Control is designed to remotely monitor, control and automate airflow in underground mines. Courtesy of Ventsim

Reliable models allow mines to plan ventilation over the short, medium and long term. This is critical for major infrastructure decisions.

“For example, something that’s extremely expensive is driving a ventilation raise,” said Pinedo. “You want to be able to do right the first time because if, in five or 10 years, you realize that you under designed it, it’s not as simple as saying, ‘we’re just going to put more air through that raise’ or ‘we’re going to buy a bigger fan’ because you can’t always do that.”

The latest version of Ventsim Design, released in 2023, has several modelling and simulation features. It can simulate contaminants such as diesel particulate matter, model the gas dispersion following a blast, and run fire simulations.

“For emergency preparedness, mines will go through worst-case scenarios. For example, if you want to see where the smoke might go, or see what would happen if there were a loss of power and your fans stopped working. The simulation tool will allow you to [do that],” Pinedo said.

The software can also incorporate manual ventilation survey measurements into the simulation, to help verify whether the model aligns with reality and fine-tune it for minimal error.

Complementing the planning power of Ventsim Design is Ventsim Control, the company’s software that can remotely monitor, control and automate airflow, heating and cooling to deliver safer, more productive and lower-cost ventilation for mines.

While the two products integrate seamlessly, Ventsim Control can be a standalone system programmed specifically for ventilation optimization.

The software offers five progressive levels of control. At the most basic level is the manual remote control of equipment such as a fan, a regulator or a door. This level can be integrated with Ventsim Design, allowing users to simulate and project different modelling outcomes.

Level two introduces automated scheduling, where ventilation settings change according to pre-programmed events such as shift changes or blasting, ensuring airflow is provided only in certain areas of the mine during specific times.

Level three adds flow and gas sensor integration, where it can automatically control setpoints for airflow for fans, gas concentrations and temperature, using PID control loops (a feedback control system that uses a mathematical algorithm to calculate error between the desired setpoint and a measured process value) to reach the most desired conditions. The gas bias control feature can also increase airflow to dilute high gas levels in specific areas.

Ventilation on demand is level four of the control system. In this mode, Ventsim Control adjusts ventilation dynamically based on the real-time location of personnel and equipment. Achieving full VOD requires enabling infrastructure such as reliable communications networks (fibre, LTE or 5G), PLC-connected hardware, environmental monitoring stations and advanced tracking systems. This integration automatically tailors ventilation to the mine’s exact needs.

At the highest level, optimization algorithms fine-tune the operation of primary fans to achieve optimal airflow distribution while reducing network resistance to airflow. This can help decrease the energy consumption of the mine and save thousands of operational dollars.