Floating photovoltaic systems by Ciel & Terre repurpose mine pit lakes and tailings ponds into renewable energy sites. Courtesy of Ciel & Terre International

The mining industry is a major contributor to global carbon emissions. Operations demand significant amounts of energy, much of it still sourced from fossil fuels, creating a heavy environmental footprint.

As climate pressures mount, mining companies are under increasing pressure to rethink how they power their mines. But transitioning to low-emission energy systems is not simple—or fast. Today, a number of energy companies are developing technologies that can reliably meet the diverse power demands of mining operations, while also paving the way for a future with more sustainable energy solutions.

Floating solar power plants

Floating photovoltaic (FPV) systems are being explored as a new option for renewable energy systems in the mining sector by companies such as the France-based renewable energy specialist, Ciel & Terre.

FPV power plant systems work similarly to traditional ground-based solar panels but instead place photovoltaic modules, which convert solar light into electricity, on floating structures anchored to the bottom or banks of inland or artificial water bodies.

Ciel & Terre has installed over 330 FPV systems across six continents, particularly in countries such as Japan, Taiwan and the United States. The company has also developed preliminary designs for some mining projects in Canada and have several engineering, procurement, and construction contracts.

The FPV systems are installed in abandoned or operational mine pit lakes and tailings ponds, repurposing them for renewable energy generation without competing with land resources. FPV installations have a 25-to-30-year life, said Chris Bartle, director of sales and marketing—the Americas, at Ciel & Terre USA.

The technical characteristics and installation conditions of FPV systems differ between mine pit lakes and tailings ponds. Mine pit lakes generally provide more stable environments for FPV deployment, while tailings ponds require more complex site-specific designs due to their chemical composition and water quality.

For mining applications, FPV systems have advantages that typical ground-based solar systems do not offer, said Bartle.

“The main advantage is you’re not taking up land that could be used to advantage in many other ways,” he said.

FPV installations also bring unique environmental benefits. Covering water with floating panels reduces evaporation by limiting the surface area exposed to the sun. “This is important in areas where drought is a problem like in California,” said Bartle. Reduction of sun exposure also slows algae growth thus reducing water contamination.

Because of the variety of water bodies FPVs can be installed on, they do require site-specific engineering considerations for their complex structural and anchoring and mooring systems, “including bathymetry, water depth, water level variation, wind loads, ice formation, snow accumulation,” said Bartle. That, combined with water chemistry concerns and occasional site remediation, makes FPV systems more expensive than traditional land-based solar systems. Bartle estimated the cost difference to be about 10 to 15 per cent more expensive.

Despite the higher upfront cost, FPV energy systems are gaining interest, according to Bartle. “We are growing in the global market,” he said.

Diesel efficiency

Scotland-based energy solutions provider Aggreko has launched its 400-kilowatt Tier 4 Final diesel generator in North America. Designed for quick deployment on skids or trailers, the generator unit provides a dependable and flexible power source for industrial and remote applications. The 400-kW unit is purpose-built for mining operations that require reliable power during utility outages, remote deployments or shifting job site demands.

Equipped with a Tier 4 Final-certified diesel engine, which meets the U.S. Environmental Protection Agency’s most strict emission standards for off-highway diesel engines, the generator achieves up to 99 per cent reductions in nitrogen oxides and particulate matter compared to earlier-generation engines. The result is cleaner air and lower overall emissions for on-site operations.

Aggreko’s 400-kilowatt Tier 4 Final generator can be paired with renewable energy sources and battery energy storage to deliver low-emission power for remote mining operations. Courtesy of Aggreko

Aggreko’s 400-kilowatt Tier 4 Final generator can be paired with renewable energy sources and battery energy storage to deliver low-emission power for remote mining operations. Courtesy of Aggreko

According to Isaac Silva, Aggreko’s mining account specialist, the generator combines the reliability of diesel power with the flexibility of hybrid integration. “Mining operations need energy solutions that can adapt as quickly as their projects do,” he said. “By combining modular design, fuel flexibility and advanced monitoring, we help our customers maintain reliable power today while also preparing them for the cleaner, more efficient technologies of tomorrow.”

At the heart of the new generator is advanced after-treatment technology, including selective catalytic reduction and oxidation catalysts, which enable it to meet the stringent Tier 4 Final standards and makes it suited for environmentally sensitive or remote mine sites, said the company.

The unit is also hybrid-ready, meaning that it can integrate with renewable energy sources and battery energy storage systems (BESS) to further reduce its carbon intensity.

“When paired with BESS, the generator can run at its most efficient output level while the batteries handle sudden spikes or dips in demand,” explained Silva. “This helps minimize idling, reduce fuel burn and extend engine life. In periods of low demand, the generator can even shut down entirely, allowing the BESS to carry the load, which further reduces emissions.”

This flexibility of the 400 kW Tier 4 Final unit directly addresses one of mining’s biggest energy challenges: managing variable power demands throughout the day at remote or off-grid sites.

Traditional generators are often oversized to meet peak load requirements, resulting in inefficient fuel use, higher emissions and increased maintenance. The 400 kW Tier 4 Final unit eliminates that inefficiency by allowing mines to scale power up or down quickly and hybridize with renewables or battery storage to stabilize power output and lower carbon footprint without compromising reliability.

“This makes it particularly valuable for bridging power during expansions, supporting new pits or supplementing weak grid connections, which are common scenarios in modern mining operations,” said Silva.

When working with clients, “we start with an initial consultation and assessment that identifies the mining operation’s energy needs, taking into consideration current and future demand,” said Silva. “Following that, our team designs a tailored energy package designed with plug-and-play scalability in mind. From there, the Aggreko team is an ongoing resource during and after deployment and integration, ensuring safe, reliable power for the site that is monitored 24/7 with the Aggreko Remote Operations centre.”

Aggreko supports clients from initial consultation through installation and operation, overseeing logistics, commissioning and integration with existing infrastructure. “Our modular assets reduce capital outlay while avoiding disruption to ongoing production,” Silva said. “We ensure minimal lead times from contract signing to power-on, which is critical for remote or fast-track mining projects.”

Reliable and flexible

In Pakistan’s remote western region of Balochistan, access to essential infrastructure such as water, power and transportation is limited. But notably, the area is home to one of the world’s largest undeveloped copper-gold deposits: the Reko Diq project, owned by Barrick Mining.

The remoteness of the project has made reliable, flexible and scalable energy systems a key requirement for the development of the mine.

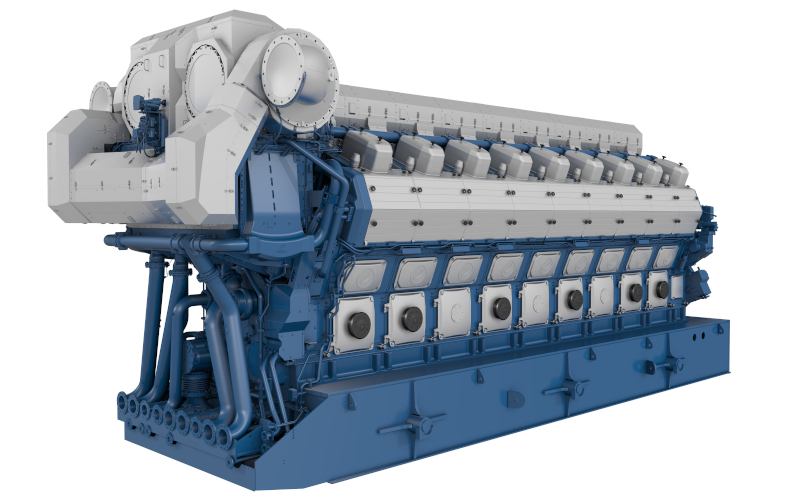

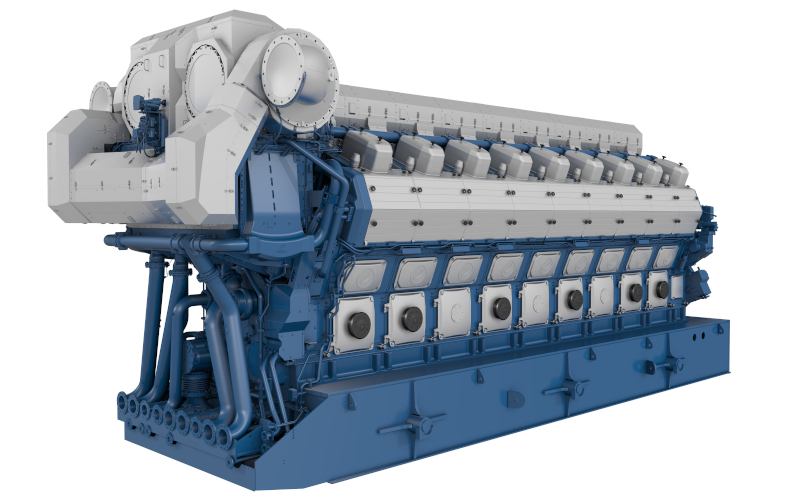

To meet that need, global technology group Wärtsilä is supplying a 204-megawatt power plant for the site. “The plant will operate with 12 Wärtsilä 50 engines and auxiliaries,” said Alexandre Eykerman, energy business director at Wärtsilä Energy, a business of Wärtsilä.

At the Reko Diq mine project in Pakistan, Wärtsilä’s 204-megawatt power plant will combine fuel flexibility and heat recovery technology to support future renewable energy. Courtesy of Wärtsilä

At the Reko Diq mine project in Pakistan, Wärtsilä’s 204-megawatt power plant will combine fuel flexibility and heat recovery technology to support future renewable energy. Courtesy of Wärtsilä

While the plant will initially operate on natural gas and liquid fuels that are easily available in the remote region, it has a future-proof design that can adapt to cleaner energy sources as they become accessible.

“The power plant will include technological provisions to enable the engines to be converted to operate with alternative fuels in the future,” said Eykerman. “Wärtsilä’s engines are fuel flexible: our engines can already run on various gas and liquid fuels and can be converted to run on more sustainable fuels whenever they become available. This means engine power plants are not tied to any fuel.”

Beyond fuel flexibility, Wärtsilä’s technology incorporates heat-recovery boilers that enable Flexicycle operation—a configuration that combines gas or multi-fuel engines with a steam turbine to boost efficiency. This setup also supports renewable integration, such as solar or wind, and allows for future grid connection as regional infrastructure develops.

“Once the renewable energy source is operational, this flexible asset will play a significant role in delivering the lowest levelized cost of electricity (LCOE),” Eykerman added, referring to the lowest average cost of generating electricity over a plant’s lifetime, including investment, operation, maintenance, fuel and decommissioning.

According to Wärtsilä, adding flexibility to power plant operations improves system reliability, keeps the grid stable and lowers the overall cost of transitioning to lower-carbon energy systems when the time is right.

In combined-cycle mode, which uses two different power generation processes such as both fuel engines and steam turbines in the same power plant to recover and reuse heat energy, the Reko Diq plant is expected to significantly increase electrical efficiency and reduce the amount of fuel and carbon emitted per kilowatt produced at the plant.