Nature hides its mineral resources well, compelling those who seek them to combine technology with creative thinking. Photo: Vincent Lock/Flickr

Mineral discovery rates are in decline worldwide. Consider gold: over the past decade, there have been just 41 new discoveries (containing 215 million ounces) compared with 222 discoveries (containing 1.7 billion ounces) in the preceding 18 years, according to S&P Global Market Intelligence.

Meanwhile, the cost of discovery has soared. It required an average of less than US$20 to find an ounce of gold two decades ago, but that figure has more than doubled in recent years, according to research by Richard Schodde of MinEx Consulting.

The crisis spares few commodities. But rather than abandon the hunt, several industry players are challenging a future of diminishing returns by developing innovative ways to uncover hidden mineralization. #DisruptMining, an annual event now in its third year, has been a catalyst in this regard, encouraging entrepreneurs to tackle mining’s biggest headaches by offering monetary rewards and prestige.

Here we look at three technologies that are not necessarily “new,” but rather novel applications of techniques that have been proven in other fields. They represent the kind of fresh, forward thinking that is required to find the ore bodies that will sustain the mining industry into the future.

Elemission’s Coriosity

The use of laser spectrometry on NASA’s rover Curiosity to provide information about soil and rock compositions on Mars has spurred a new wave of interest in laser-induced breakdown spectroscopy (LIBS) for real-time exploration here on earth.

The main advantage LIBS has over portable X-ray fluorescence (XRF) is that it can detect lighter elements of the periodic table such as lithium, carbon and sodium that XRF is blind to. Boston-based SciApps introduced the first handheld LIBS analyzer in 2014, followed by Elemission’s Coriosity, a fully-automated core scanner for multi-elemental imaging, in 2016.

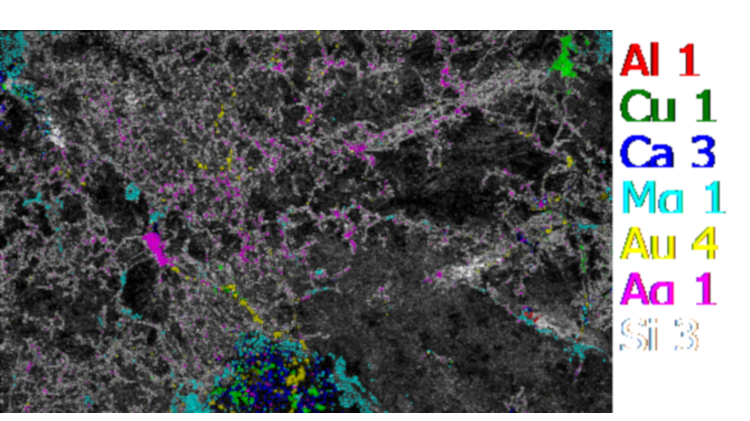

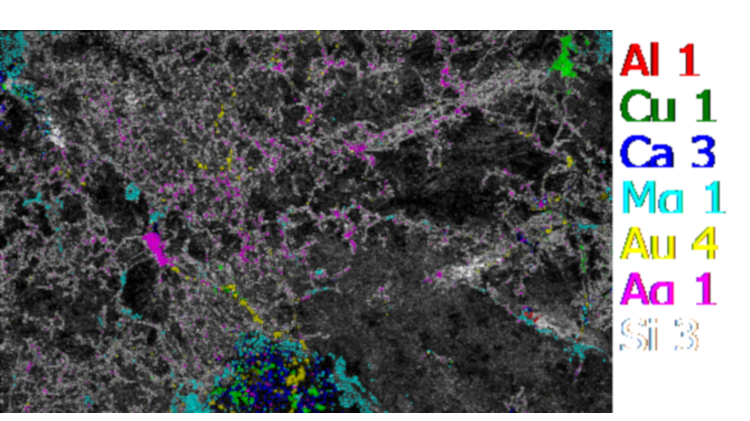

The speed and resolution of the technology continues to improve. The LIBS technology generates a colour-coded map of elements in the sample. Courtesy of Elemission

The speed and resolution of the technology continues to improve. The LIBS technology generates a colour-coded map of elements in the sample. Courtesy of Elemission

“Since then we’ve increased the speed to 1,000 measurements per second, about 100 times faster than our competitors,” said François Doucet, who founded Elemission with co-CEO Lütfü Özcan in Montreal, Quebec. “We produce a high resolution elemental map with a special resolution of 50 micrometres.”

Coriosity is designed to be rugged and easily operated at exploration and mine sites, eliminating the cost and time required to send core samples to the lab. Because the signal acquisition is automated, field geoscientists do not have to worry about keeping still to acquire an accurate reading. Working at its highest resolution of 50 micrometres the scanner can analyse one cm2 in less than 40 seconds, can accommodate a sample as large as 16 cm2 and stitch together a series of scans along a given sample. A bench-top unit can manage a sample of up to 25 centimetres long and consumes about 1.2 kW of electricity while operating, about the equivalent of a microwave oven.

Elemission continues to improve the technology and expects to unveil a new tomography tool this year. The refinement will allow geoscientists to take small slices of rock, analyze them and reconstruct the rock in 3D without destroying the original sample.

Acoustic Zoom

This ultra-high frequency 3D imaging technique uses seismic waves to help map complex geological formations at depth. The technology is adapted from oil and gas exploration, where traditional methods required tweaking to find the subtle discontinuities that characterize the new generation of shale gas deposits.

“All of a sudden, we recognized the work we were doing with fissures in shales could be relevant for mining, where what you are trying to do is characterize mineralized veins or faults that potentially hold great value,” said Jacques Yves Guigné, chief geophysicist and CEO of Acoustic Zoom.

The breakthrough allows companies to fill in the geology and find new targets between widely spaced drill holes, and netted Acoustic Zoom first place at the #DisruptMining 2018 competition co-hosted by Goldcorp and KPMG. The prize gave the fledgling Newfoundland company $1 million and a chance to pilot the technology at Goldcorp’s Red Lake mine.

Is Canada losing the exploration game?

Guigné explained that acoustic energy is either reflected, diffused or attenuated. While the reflected portion is important in traditional oil and gas exploration because it can indicate changes in strata, the diffused or scattered portion is more valuable in mineral exploration because it identifies changes in density and/or speed of sound that can indicate a mineralized body or conduit for mineralization. Acoustic Zoom’s algorithms process the acoustic data in a way that provides detailed spatial imagery around the drillhole, saving drilling costs and identifying new targets.

The technology uses a hydrophone array mounted along the borehole to map geology in a 200-metre diameter around the hole to a depth of 500 metres. Using the Goldcorp prize money, Acoustic Zoom has adapted the array for use not only in surface exploration, but in underground exploration to pinpoint the direction of mineralized zones or identify geohazards before further development.

“We’re now moving into Australia, Argentina, Peru, and Colorado,” said Guigné, who declined to name the projects for confidentiality reasons. “For example, we’re looking at the conditions that lead to uranium mineralization in an area that has been investigated with traditional seismics. We can provide the resolution and sensitivity they need to decide where to drill with much less risk and cost.”

Goldcorp’s cognitive journey

IBM’s Watson has been finding answers in unstructured data for years, but it is only recently that the artificial intelligence has been tasked with finding new gold mineralization. Teaming up with Goldcorp at the Red Lake mine in northwestern Ontario, IBM Canada is coaching Watson to predict where new pockets of gold might lie by churning through, and learning from drill-hole data, chip data, maps and geological models around locations of interest.

“The clustering of geovariables is in line with what geologists are already doing, but Watson can just consume a whole lot more data,” said Max Howarth, a geological engineer and managing consultant for IBM Canada. “Every few days, we run a set of predictions on a well-defined area and the geologists examine it in 3D and say how good – or bad – the model is.”

Related: With more mines being connected, how are they being protected?

Phase one of Goldcorp’s cognitive journey began in late 2017 and involved educating Watson about what to look for and inputting and checking the integrity of 80 years’ worth of data – including unstructured analysis and maps – to provide insights into Red Lake’s geology and successful exploration techniques and narrow down areas of interest. What would have taken geologists an estimated 165 hours to stitch together took Watson less than a day.

During phase two the following spring, the Goldcorp-IBM team asked Watson to identify correlations within the data, interpret other datasets, and work with geologists to improve infill geology and make predictions about areas with limited data. The predictive modelling relies on convolutional neural networks, explained Howarth, which have traditionally been used for image recognition in two dimensions. “Creating a custom model architecture that can work in three dimensions was a significant area of research – particularly since the geological data being consumed is very unique when compared to data from other industries like banking or retail.” To prepare the geological data for the predictive model, IBM borrowed from an AI technique used in natural language processing – “word embedding” – where similar words are grouped together. “We use both data driven investigation and input from geologists to create geological embeddings,” he said. “These embeddings capture conventional and tribal geological knowledge and dramatically reduce dimensionality of data, while preserving the detail.”

The latest iteration, dubbed IBM Exploration with Watson, extends farther afield, exploring areas near the mine that have even less information. So far, Watson has used the powerful algorithms and predictive modelling developed in phase one and two to identify nine new targets at Red Lake.

Goldcorp drilled three of them in 2018 with “very positive results,” according to IBM’s Mark Fawcett, and was investigating the rest in late December. Fawcett said IBM is also testing Exploration with Watson on two less advanced “non-gold” projects in Canada and South America but could not name them due to confidentiality agreements.

The vein that runs through all of these approaches is the adaptation of existing technology and computing power to the specific demands of geoscience to make mineral exploration more productive and economical. If events such as #DisruptMining can keep the momentum going, they may just be able to reverse the trend toward diminishing returns on exploration investment.