Lucy Hunt. Courtesy of the Saskatchewan Research Council

Sensor-based sorting (SBS) has grown significantly in the mining industry over the past decade, driven by the need for efficiency, cost reduction and sustainable practices. Laser-based particle sorting systems, a subset of SBS, uses laser technology to differentiate and separate valuable ore minerals from waste rock based on their optical properties. The technology offers a new opportunity to concentrate different ores and can significantly upgrade low or marginal grade deposits by selectively isolating and concentrating high-grade material, which can enhance the economic viability of deposits.

The environmental benefits of laser-based ore sorting are also significant. By efficiently separating waste rock from ore, laser sorting reduces the volume of material that needs to be processed downstream, translating to lower energy consumption and decreased emissions, therefore contributing to more sustainable mining practices. Additionally, laser sorting eliminates the need for chemicals, allowing for a dry processing method that minimizes environmental impact. Early removal of penalty elements, such as arsenic in arsenopyrite and mercury in cinnabar, and other deleterious minerals through laser sorting can also enhance subsequent processing efficiency and ensure cleaner tailings, thereby enhancing the sustainability and cost-effectiveness of mining operations.

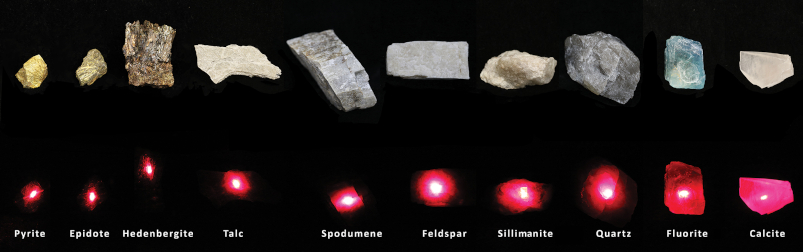

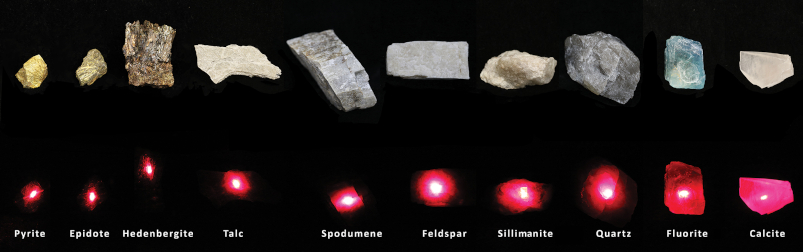

Laser sorting exploits the scattering property of light in minerals. The light is scattered to varying degrees based on the structure and composition of the minerals, creating a measurable glow. Detectors capture scattered light and differentiate between valuable minerals and waste material. Translucent minerals, such as quartz, scatter light throughout their crystals, while opaque minerals show little to no measurable scattering. The scattering patterns and intensities are unique to different materials, enabling laser-sorting systems to distinguish between valuable minerals and barren rock, and help sort minerals based on their optical properties.

For example, laser sorting has proven highly effective for quartz-hosted gold deposits. Gold is not detectable with current sensors, which means sorting relies on proxies, like quartz. These deposits feature gold-bearing quartz veins within various host rocks, formed from silica-rich hydrothermal fluids. These fluids migrate upwards, precipitating as they reach lower pressures, forming either gold-hosted or barren veins. These veins may exhibit multiple stages of mineralization and remobilization. The gold is typically finely disseminated within the quartz matrix and traditional sorting methods, such as gravity separation, often fail to distinguish between quartz with high gold content and barren quartz. Quartz is a hard mineral that requires significant energy to crush, so without efficient separation of gold-bearing from barren, it could lead to higher processing costs and lower recovery rates.

Laser technology detects subtle differences in the composition of ore-bearing and barren quartz. Gold-bearing quartz often has minor variations in texture, colour and other surface characteristics compared to barren quartz. Laser interactions with quartz exhibit different scattering properties, enabling the effective separation of gold-bearing quartz from waste material.

Image showing the scattering effect of a laser on different minerals and rock types. Courtesy of the Saskatchewan Research Council

Image showing the scattering effect of a laser on different minerals and rock types. Courtesy of the Saskatchewan Research Council

Characterizing the ore prior to sorting is an important step for optimizing the performance of the system. Detailed knowledge of the ore’s properties ensures that the sorter can be calibrated for the best results. Traditional gold deportment studies, including bulk mineral analysis, should be performed to understand the deposit. These studies can highlight any penalty elements, which may be beneficial to remove early in the process. Optical and electron microscopy can be used to study the size, shape and distribution of gold particles within the quartz matrix, which is crucial for understanding how the gold is hosted and can be liberated.

Once the mineralogy has been determined, the scattering response of the different minerals can be compared to determine the best setup for the sorter. By graphing the relationship between light scattering and gold content, the effectiveness of different laser settings in achieving the desired outcomes can be assessed. Laser scattering can identify and sort minerals based on subtle shifts in the wavelength of scattered light, providing further avenues for enhancing sorting accuracy and efficiency.

By using laser-sorting technology to analyze the intensity, wavelength and direction of light dispersion, information about particle size, shape, composition and even molecular structure can be gathered, which can enhance an operation’s sustainability, efficiency and cost effectiveness, and can significantly upgrade low or marginal grade deposits.

Lucy Hunt is a supervisor in the technical services division of the Saskatchewan Research Council (SRC). She is part of the team responsible for implementing SRC’s SBS initiatives.For more information on the SRC’s SBS technology solutions, visit src.sk.ca.