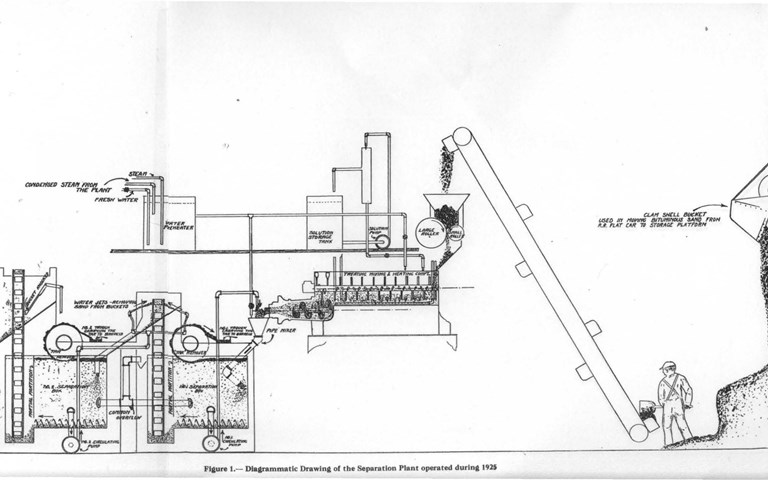

This drawing, originally published in the 1929 CIM Bulletin article “The Separation of the Bitumen from Alberta Bituminous Sands” by Karl Clark, depicts a hot water separation plant as it was configured in 1925 at a test site in Edmonton.

The development of the Athabasca oil sands has re-shaped the landscape of a once quiet corner of northern Alberta into an energy powerhouse. CIM was there every step of the way, from the earliest research and discoveries to the first commercial operation and beyond.

It was not until the turn of the century that researchers began to study the oily soil of northern Alberta in earnest, and it would be decades more before the bitumen mixture could be processed into oil.

One of the first practical uses was asphalt, as noted in the CIM Bulletin in 1928.

“In 1915 the Department of Mines experimented with the use of the crude sand as a paving material on several streets in Edmonton, with results that have been entirely satisfactory.”

Back then, exploitation of the resources was hobbled by logistical challenges. A lack of adequate rail lines made shipping the asphalt to market difficult. Yet even with these barriers, it was a viable option.

CIM featured some of the pioneers of oil sands development, including Karl Clark, whose work was shared in a 1929 CIM Bulletin.

Clark noted that “the status of such oils as the bitumen content of the bituminous sands for gasoline manufacture has been completely changed. While refining depended on straight distillation, oils of this sort were worthless for this purpose. But with the new methods of cracking, these same oils can be broken up by heat and pressure into surprisingly large yields of motor fuel…There is no great technical difficulty about using any oil or bitumen for gasoline manufacture. Whether it is practical to use them is almost entirely a question of economies.”

Over decades Clark invented and refined a method of using hot water to separate the bitumen from the sand, by liquefying the mixture and filtering the oil out, which is still the basis of modern oil sands operations today. He also followed others’ work to solve the puzzle of the oil sands with interest, and in a 1948 CIM Bulletin observed a common frustration among his processing peers.

“Full-scale design of bituminous sand separation plants has been considered and attempted mainly by mining men experienced in the concentration of minerals. Such men just naturally turn to watery pulps and pronounced aeration as in flotation cells. Unfortunately, such pulps and degrees of aeration do not work properly in the case of bituminous sands.”

Commercial operations began in the 1960s, and the innovation in the oil sands that was started by Clark continued. In the 1990s, a new method introduced by Syncrude, dubbed hydrotransport, combined ore and hot water closer to the working face to create a slurry that was pumped to the upgrading plant. This innovation made the extraction process more efficient, though it demanded more comprehensive instrumentation and monitoring of the extraction process.

The mining process also shifted from bucket wheel excavators and draglines to hydraulic shovels for more selective mining. Add to that the successful development of in situ extraction, and the oil sands, through hard work and perseverance, have matured from an engineering puzzle to the foundation of this country’s energy reserves.

Further reading

These CIM Bulletin papers are available on CIM’s technical paper library

Bituminous Sands of Northern Alberta by S. Ells and A. Swinnerton, 1937

Hot-water Separation of Alberta Bituminous Sands by K. Clark, 1944

Pilot Plant Investigations on Cold Water Separation of Bitumen from Alberta Bituminous Sands by L. Djingheuzian, 1952

Current Exploratory Techniques in the Athabasca Bituminous Sands Area By W. Gallup, 1960

Development of the Heavy Minerals Potential of the Athabasca Tar Sands by L. Trevoy, R. Schutte, and R. Goforth, 1978

Technology transfer and acceptance key to increased productivity in oil sands mining by R. Singhal, 1989

AOSTRA underground test facility: progress and potential by J. Hasten, R. Luhning and S. Gittins, 1990

Improving reliability and productivity at Syncrude Canada Ltd. through materials research: past, present, and future by M. Anderson, S. Chiovelli, and S. Hoskins, 2004