The Bhuj factory, where both small and giant tires are made, receives energy and steam from a 20-megawatt coal cogeneration plant on the site. Courtesy of BKT Tires

The Indian manufacturer BKT Tires is making a big push to gain more ground in the global mining tire market. The company, already an established supplier for underground haulage equipment, is moving to the open pit. Last fall the company, which is ramping up a US$500 million modern manufacturing facility for off-the-road tires near the coast in northwestern India, passed an important milestone with the Caterpillar certification of its 35-inch tires for use on 775 and 777 haul trucks.

The company said it currently has a six per cent share of the mining market and would like to bring that up to 10 per cent by 2017, supported by the strategic location of its new factory near Bhuj, in the Gujarat province.

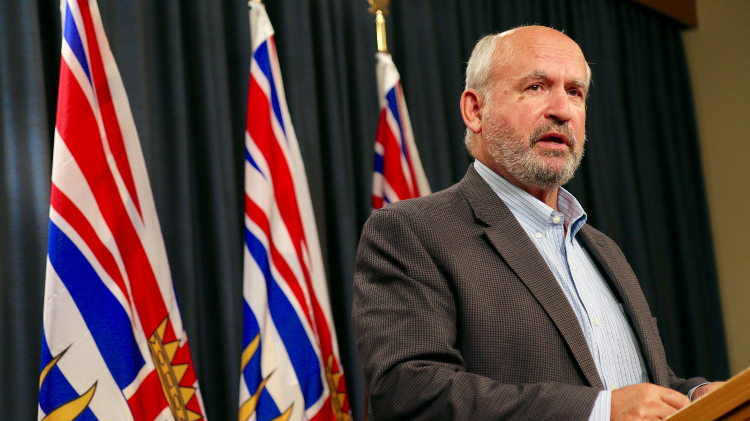

“Today [mining] is slow, but we know it is going to come back,” said Rajiv Poddar, BKT’s joint managing director, who led the drive to build the new plant. According to Poddar, the combination of state-of-the-art equipment, proximity to a large port facility on the Arabian Sea, and low labour cost relative to its competitors making tires in Europe and Japan, gives the company a competitive advantage. “We have a lower cost per tonne than Michelin and Bridgestone and we produce better tires than the Chinese,” he said at a December press event in Mumbai.

The Bhuj plant made its first tire in March 2012, currently turns out 150 tonnes of a range of earthmover, industrial and agricultural tires daily, and has the capacity to double that output, if necessary.

For now, the maximum size the giant tire facility at the plant yields is a 49-inch traction tread tire designed for 90-tonne haul trucks. According to Keshav Das, head of OTR Tire sales and technical services for Canada, the 49-inch tires will be ready for field trials in the first half of 2016. A 51-inch model is in development and the plant has the ability to do complete quality control testing – X ray, spherometer and endurance – up to 57 inches. Giant tire demand has declined sharply since the plant was conceived five years ago so it does not have a second production line installed, but does have the space if expansion is required.

Another key to accessing the mining market, said Das, is the shift away from working with wholesalers to distributors who understand clearly the requirements and constraints that mine operators have. Today BKT, through partnerships with OK Tire, Kal Tire, Tiremax and Unimax, has distribution across Canada. “A servicing dealer is able to deliver top-notch service to the mine site, focusing on those precise requirements of the site be it higher efficiency, better economy or improved productivity,” explained Das.

BKT, which generates most of its revenue in the agricultural tire market, began making all-steel radials for the mining sector in 2008 at one of its three pre-existing plants in India. In addition to the recent Caterpillar certification, Poddar said the company is busy building relationships with other equipment manufacturers, including Komatsu.