We, the editors of CIM Magazine, took a look back at the many stories we covered in 2019 and are highlighting those that we think capture the zeitgeist of the year. The tragedy of the Córrego do Feijão tailings dam failure in January focused a lot of our coverage in 2019, but there were plenty of novel ideas, promising technologies and clever engineering to draw from as well.

Social standing

Mining is an inherently risky business and investors are starting to demand more clarity about environmental, social and governance (ESG) risks. It’s not just the immediate interest in tailings management that is spurring investors to make those demands, Kelsey Rolfe notes, but part of a larger trend of socially responsible investing. For miners to do business today, it’s essential to meet ESG demands head on. – Michele Beacom

The complex journey to a simple solution

It didn’t make sense to the operations team at Niobec why they kept experiencing seasonal variations in their flotation circuits. Every winter, niobium recovery rates at the mine in Saguenay region of Quebec dropped while reagent consumption increased. Figuring out what the problem was and how to solve it became an 18-month investigation requiring the application of logic and the adoption of a step-by-step problem-solving process. In the end, it turned out there wasn’t one single factor but an interconnected puzzle. – Carolyn Gruske

The long view

Almost three decades ago, the Inuit communities of Nunavut took on a massive challenge in trying to secure the territory’s most valuable mineral rights. The hard work and planning the Tunngavik Federation of Nunavut – and the mineral advisors assisting them – put into making sure the local communities received the benefits of mine development reflects the same challenges Indigenous communities face today. – Matthew Parizot

The golden key?

Allan Cramm of Anaconda Mining knows that the island of Newfoundland is laced with narrow-vein gold deposits. The puzzle for him has been how to mine them without losing all the money down the hole. A discussion a few years back with a Memorial University professor, a.k.a. “King of the drill,” with a deep background in oil and gas extraction yielded an intriguing idea. Anaconda has been testing the directional drilling method on The Rock, and attracting the interest of gold miners from around the world. – Ryan Bergen

The internet of tailings

With Internet of Things, the tools to monitor tailings dams remotely and in real time are available. Cecilia Keating looked at a number of companies that are addressing the data acquisition and data management systems and platforms that are the basis for modern tailings storage facility monitoring. These tools offer miners a second set of eyes and a round-the-clock monitoring solution to complement boots-on-the-ground inspections. – Michele Beacom

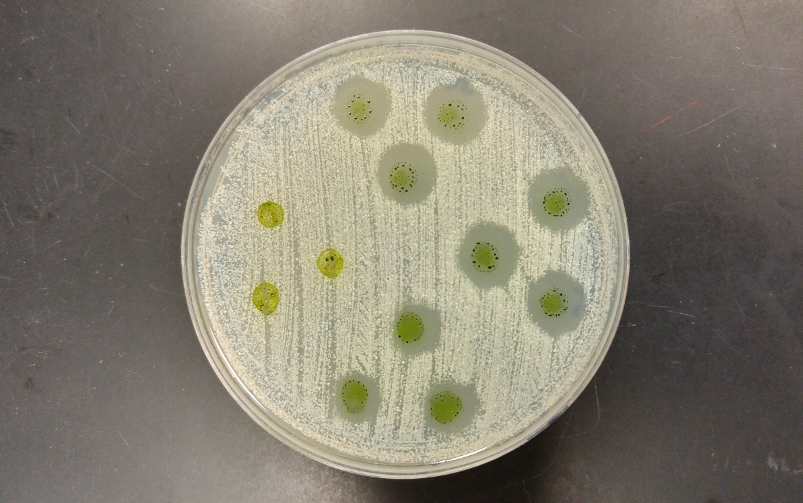

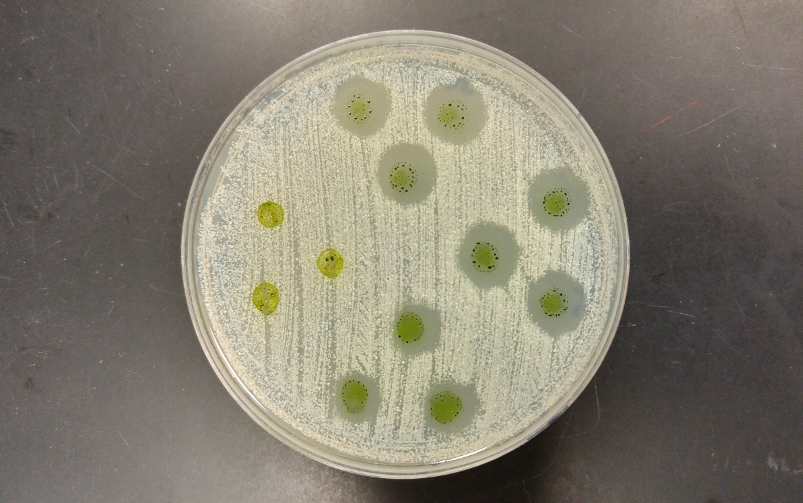

Green goop yields a breakthrough

Tailings ponds are seen as a problem the mining industry needs to solve, but a pair of researchers sees them in a different light: as a possible solution to a medical crisis. Professor John Ashley Scott and microbiologist Gerusa Senhorinho from Laurentian University have discovered that some microalgae that grows in acidic tailings ponds can have antibacterial properties that are effective against the bacterium Staphylococcus aureus – a potentially deadly strain of bacteria that can be resistant to common antibiotics. – Carolyn Gruske

The Artificial Intelligence test

It has been the fashion recently at industry events to at least be heard talking about the opportunities of artificial intelligence such as machine learning. Those exploring what challenges such technologies can solve and actually putting them to work in operations are fewer in number. Cecilia Keating talked to some of the miners who are applying the tools to operations – and seeing encouraging results – to give some guidance on managing the human angle of AI adoption as well as highlight the resources now available to help miners get projects underway. – Ryan Bergen

Canada primed for rare earth revival

While the expected boom in 2010 never panned out, the ongoing slinging of tariffs between the United States and China has woken up the American markets to the value of creating a new supply chain for rare earth metals. While it remains to be seen whether companies can turn a profit from these niche metals, Canada is in a unique position to benefit from the increased demand – thanks in part to the rise of battery electric vehicles. – Matthew Parizot

Remote patrol

Hired to clean up the Mount Polley mine tailings dam breach, Golder Associates rebuilt the dam, rehabilitated the environment and conducted studies on the impact of the breach and of the remediation efforts – all with an eye to bringing back fish and wildlife to the area. In order to accomplish that goal, however, Golder needed a way to monitor the stability of the creek environment, so it took to the air with camera-mounted drones. – Carolyn Gruske

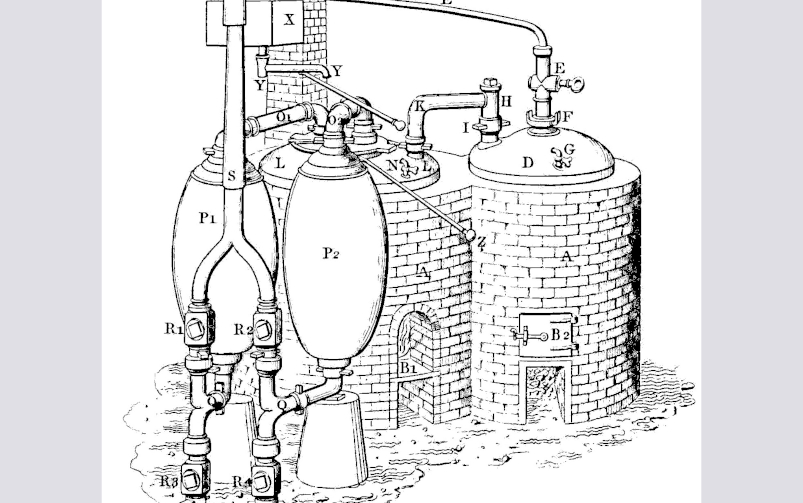

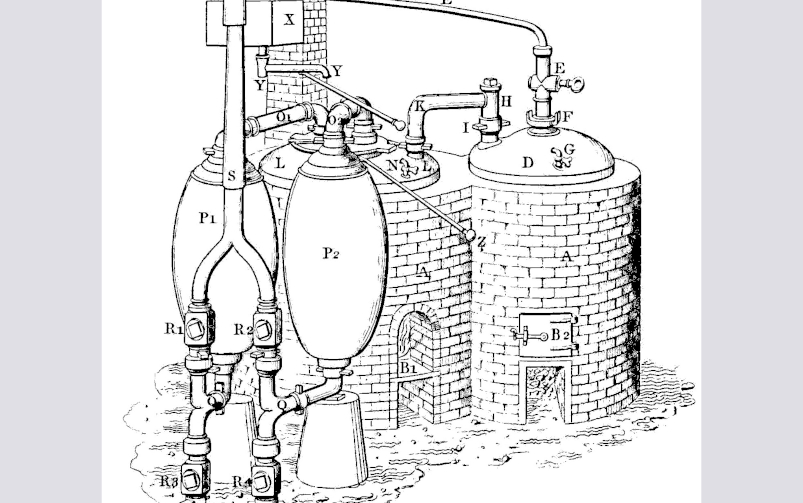

The miner’s friend

When I was researching topics to assign for our Mining Lore section, I couldn’t believe my eyes when I discovered the story of Thomas Savery and his steam engine’s connection to mining. While Savery’s engine wasn’t truly the machine that sparked the Industrial Revolution, his story points to just how connected we all are to mining in our everyday lives, whether we know it or not. – Matthew Parizot

The Essentials of Closure

For mine closure specialist Neeltje Slingerland, “dam stability, cost, environmental impact, and reclamation success now and in a thousand years can all be positively impacted with better planning.” Gillian Woodford’s profile outlines Slingerland’s four commandments of planning for closure, and clearly illustrates the mental shift about tailings taking place in the mining industry today. – Michele Beacom

Excellon wins the water war

Not long ago Excellon Resources devoted nearly as much of its workforce to an on-the-fly battle with water inflow at its Platosa mine in Mexico as it did to mining its high-grade silver ore. To get out in front of the problem, the operations team took a step back to determine where the water was coming from and to devise a strategy for keeping it out of the mine. Today the permanent dewatering operation at Platosa moves 40 million gallons of water each day, and allows the miners to focus their efforts on extracting ore. The group behind the project told us how they did it. – Ryan Bergen

What do you think will set the agenda for 2020? We would love to hear your thoughts. Write us at editor@cim.org.