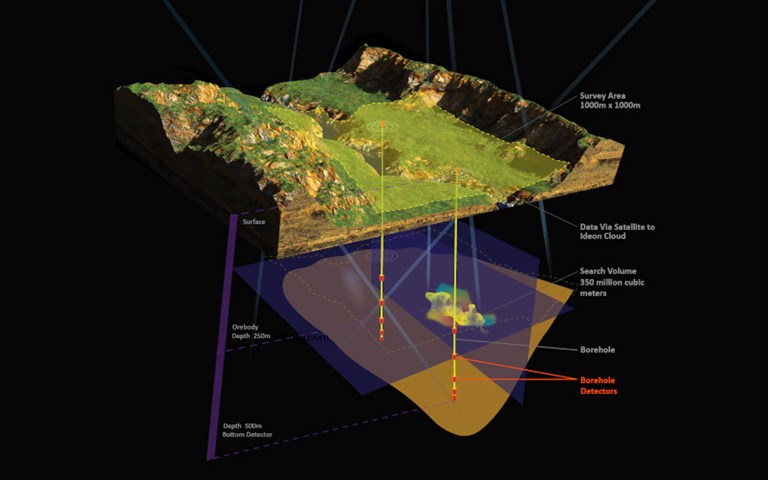

A diagram explaining how Ideon's mineral detection process works. Courtesy of Ideon Technologies.

Cosmic rays originating from the depths of space might soon find a use in exploring the depths of the earth, as one Canadian start-up has developed a new method of locating underground mineral deposits using the subatomic particles produced by these rays.

Vancouver-based Ideon Technologies – formerly known as CRM Geotomography and created as a spin-off from TRIUMF, Canada’s national particle accelerator laboratory located at the University of British Columbia – is gearing up to introduce its “cosmic-ray muon tomography” mineral deposit detectors, which the company claims can “reduce exploration drilling activities by ten times and can identify exploration targets with 95 per cent or higher certainty.”

The detectors are designed to enhance, rather than replace, traditional exploration drilling. Once a company has drilled a hole and retrieved the core sample, the detector can then be inserted into the very same drill hole, creating a 2D image of mineral deposits in the surrounding area down to a distance of one kilometre underground. With the use of multiple detectors in multiple holes, a 3D image can be constructed to precisely locate and define the mineral deposit.

The detectors measure muons, sub-atomic particles created when cosmic rays (high-energy protons and atomic nuclei) originating from outside the solar system enter Earth’s atmosphere, collide with elemental atoms and molecules like oxygen and nitrogen and then decay into smaller, radioactive, secondary particles that shower down through our atmosphere at the speed of light. While the science behind the detectors may seem complicated, Ideon’s vice-president of product Don Furseth, explained that the way the detectors find mineral deposits is analogous to a common medical procedure weare all familiar with.

“If you’re familiar with X-ray images, you can see bones and structures in the human body,” Furseth told CIM Magazine. “The way this works is very similar in terms of when X-rays pass through matter like bones you can see where things are more dense by looking at the image. It’s exactly the same process, it’s just on a different scale. Rather than looking inside a human body, we’re looking into the earth, and rather than penetrating through centimetres we’re penetrating hundreds of metres.”

Related: A recent Geoscience BC study sampled treetops for halogen elements to detect underground mineral deposits

Using the borehole detectors, companies will be able to be more selective about where they decide to drill, says Furseth, which would be helpful for an industry which the company says “has invested US$198 billion in exploration over the past 10 years with an [approximately] 45 per cent return on investment.”

“If you’re searching the area, rather than drilling a lot of holes, you can be more selective,” Furseth said. “Do one-tenth the number of holes and have them spaced further apart and then from each hole essentially look around and see if there’s something dense.”

The detectors have been in development for several years and were previously too large to fit into a borehole, severely limiting the usefulness of the product. According to recently appointed CEO Gary Agnew, shrinking the size of the detector was key to its success.

“That borehole product really takes us from a solution that [only] works in brownfield mine sites with existing mine shaft infrastructure,” Agnew said. “We were kind of locked into that part of the industry, but now the borehole detector opens up both green and brownfield opportunities.”

Ideon has performed several case studies with mining companies such as at Teck Resources’ MX700 lead-zinc deposit at the Pend Oreille mine in Washington, U.S.A. and Nyrstar’s Price zinc-copper deposit at its Myra Falls underground mine in British Columbia. During the company’s latest case-study at Orano and Cameco’s McArthur River uranium mine in Saskatchewan, the detectors located a high-grade uranium deposit under 600 metres of sandstone.

“This is a severely compact, needle-in-a-haystack type of orebody, and basically, conventional techniques can’t find these -[deposits],” Furseth said. “They’re hard to discover, so this was quite an exciting breakthrough for [Cameco and Orano.]”

The borehole detector is still undergoing trials, and the company is aiming for them to be commercially ready sometime in 2021.