Magnetic separation is underutilized in many mineral processing plants. Is this because it is an old technology and lacks the appeal of new technologies? You may be surprised to know this “old” technology is robust, has high throughputs, is relatively low cost and does not contaminate the environment. Processing plants could capitalize on magnetic separation technologies to reduce their environmental footprint while more efficiently recovering a range of valuable minerals.

Although the technology has fallen out of favour with some people, there have been advancements in the field of magnetic sorting in the last decade.

Rare earth elements have improved the strength of magnetic separators, enabling processing plants to sort minerals with weak magnetic properties.

Kappabridge magnetic susceptibility meters accurately measure the magnetic properties of minerals down to the 0.1 grams necessary for quantifying magnetic differences.

Magnetic tracers have been developed and are used to set up magnetic equipment, to make comparisons between magnetic equipment and processes and for spiking samples for audits.

These advances have significantly improved the magnetic separation process and have created new opportunities for where a separator can be applied in a plant to improve processes and reduce costs. When implemented correctly, magnetic separation offers an opportunity to recover a variety of valuable minerals residing in host ore.

Magnetic susceptibility

Magnetic susceptibility is a measure of how susceptible a mineral is to a magnetic field. The higher the magnetic susceptibility, the stronger the force of attraction to a magnetic field. A negative magnetic susceptibility implies the mineral is repelled by a magnetic force.

Minerals have a range of magnetic properties, and are categorized from high to low as:

» Ferromagnetism (cobalt, nickel and iron)

» Ferrimagnetism (ilmenite and magnetite)

» Paramagnetism (chrome diopside and garnet)

» Diamagnetism (quartz, diamond and zircon)

Both ferro- and ferrimagnetic minerals have high magnetic susceptibilities, greater than 1,000 x 10-8 m3/kg. These minerals can be sorted with weak barium ferrite magnets. Paramagnetic minerals have lower magnetic susceptibility, in the region of 50 x 10-8 m3/kg, and can be sorted using strong neodymium magnets. Diamagnetic minerals have negative magnetic susceptibility values, in the order of -5 x 10-8 m3/kg, and are repelled by a magnetic force. Diamagnetic minerals report to the non-magnetic fraction of a dry magnetic separator.

Knowing what magnetic properties your minerals contain allows you to more effectively design processes and set up equipment to further concentrate the ore and to discard waste.

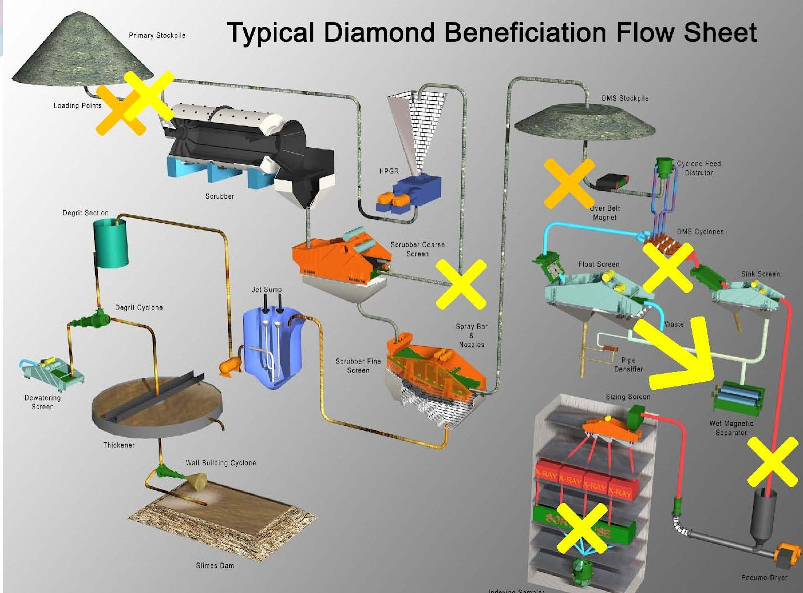

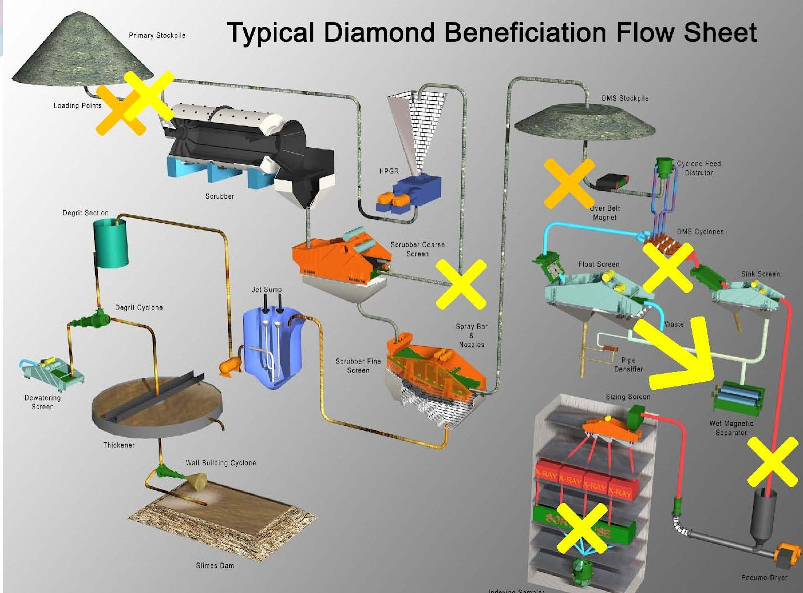

In this example flow sheet, the yellow crosses identify where a magnetic separator could be included. The gold crosses indicate the locations for overband magnets for removing tramp iron. Courtesy of Multotec

In this example flow sheet, the yellow crosses identify where a magnetic separator could be included. The gold crosses indicate the locations for overband magnets for removing tramp iron. Courtesy of Multotec

Before you use a magnetic sorter, you need to measure the magnetic susceptibility of your minerals of interest. A kappabridge magnetic susceptibility meter tells you how susceptible a particle is to magnetization. It measures negative and weak positive magnetic forces (i.e., diamagnetism and paramagnetism), as well as strong positive magnetic forces (i.e., ferro- and ferrimagnetism). This information helps determine the magnetic differences for sorting and the magnetic cut-points in order to optimize the magnetic separation process.

Related: Combining microwave transmitters with tunnel boring machines may lead to more efficient mining operations

Magnetic sorters and applications

Once you know the magnetic susceptibilities of your minerals, you can start determining what magnetic sorting equipment is required for your plant.

There are a variety of magnetic sorters with a wide range of magnetic field strengths for numerous applications in a processing plant. In a flow sheet, the ferro- and ferrimagnetic particles are recovered first, followed by the strongly paramagnetic particles, then the weakly paramagnetic particles and finally the diamagnetic particles. The ideal sorting setup has three stages:

Stage 1: A weak magnet and a high belt speed to recover ferro- and ferrimagnetic material

Stage 2: A medium-strength magnet and/or a slower belt speed to recover strongly paramagnetic minerals

Stage 3: A strong magnet with a slow belt speed to recover the weakly paramagnetic and diamagnetic minerals

On the other hand, if your ore contains mainly ferro- and ferrimagnetic minerals for recovery, then a one-stage magnetic separation process with a weak magnet is adequate.

Calibration

Magnetic tracers are simulants of varying magnetic susceptibilities from weakly paramagnetic to ferromagnetic and assist in calibrating magnetic separators and identifying operational parameters. Once you know the magnetic characteristics of the minerals, you can use magnetic tracers to identify the required belt speed and splitter plate position for processing each size fraction. It’s then possible to identify the optimum magnetic processing parameters.

Properly configured magnetic sorters placed in key locations in the processing plant can be used to recover a variety of valuable minerals in ore, which can increase a plant’s revenue and decrease waste.

Not bad for an “old” but tried-and-true technology.

For more information about magnetic separation, download SRC’s white paper.

Jane Danoczi, Pr.Sci.Nat, B.Sc. (Physics & Applied Mathematics), M.Sc. (Metallurgy) is part of the Saskatchewan Research Council’s Process Development team. She has 28 years of experience in the research and development of technologies used in mines.