W e, the editors of CIM Magazine, sat down together to look back at the many stories we covered over the last year and highlight a few of our favourites. Some we chose for how they capture the moment mining is in -- or the direction it is heading -- others for their insightful reporting and some because they were just a fun read.

Standard-bearers

It was a tale far stranger than fiction. In March 1997, when standards for public disclosure for mining companies were virtually nonexistent, the industry was primed for a hoax. But even as Bre-Xphoria mounted, CIM was in the process of developing definitions and guidelines for reporting mineral resources and reserves, which would become critical to restoring public and investor trust in junior mining companies after Bre-X’s fall from grace. For CIM Magazine’s year-long series celebrating CIM’s 120th anniversary, Virginia Heffernan spoke to Ontario Securities Commission CEO Maureen Jensen and Roscoe Postle Associates president and CEO Deborah McCombe about a pivotal moment in the history of the industry – and of CIM. – Michele Beacom

Underground turnaround

It has been a heady few years for North American Palladium and its Lac Des Iles mine in Ontario. In 2015 its finances were in bad shape, its shares were suspended from trading and its workforce was cut significantly. Today the size of the mine’s workforce has rebounded, the palladium price is strong and throughput at the mine is set to double. Graham Chandler spoke to the NAP team in March to explore the mining methods and technology improvements that have helped turn the company around. – Ryan Bergen

A staged start-up

Introducing innovative technology into the mining industry is difficult; many companies are wary of taking a potentially costly risk. So Woodgrove Technologies’ co-founders Glenn Dobby and Glenn Kosick took an unconventional route: they bought shares in Anaconda Mining and took seats on the board so they could pilot test their staged flotation reactor (SFR) at the company’s Pine Cove gold mine in Newfoundland. Virginia Heffernan spoke with the Glenns about the origins story behind their now famous flotation cells. – Tom DiNardo

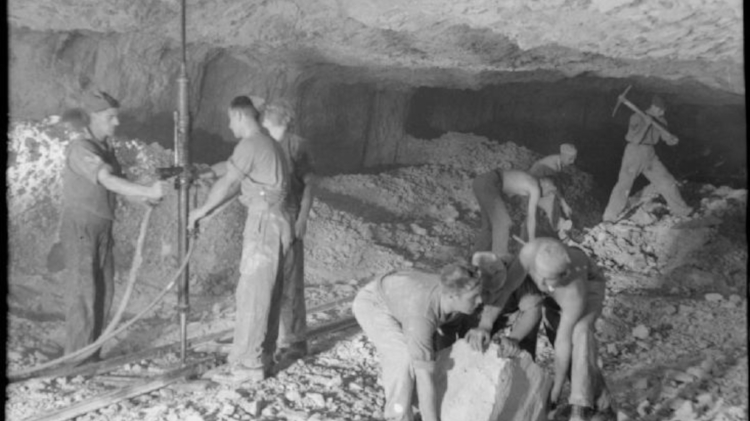

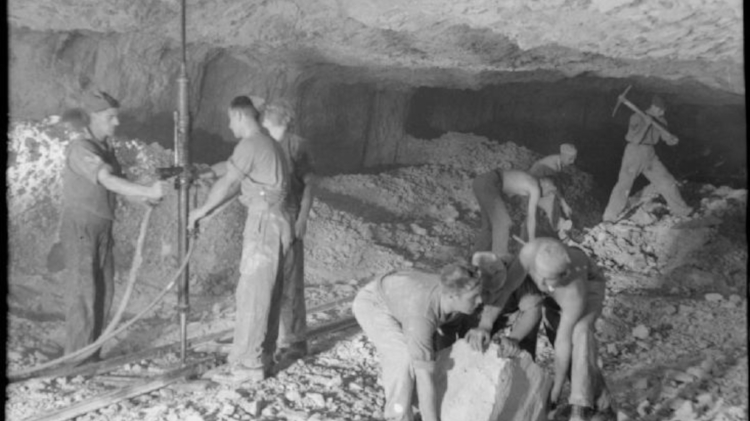

Hard rock mining on the Rock

The Rock of Gibraltar is honeycombed with more than 50 kilometres of tunnels, the majority of which were dug during the Second World War by Canadian miners. Their hard rock mining expertise was called upon by the British government after it realized that its own troops were struggling with the tough Gibraltar limestone. In November, Cecilia Keating wrote about the major mining projects carried out by two Canadian tunneling companies. – Kelsey Rolfe

Six strategies for cutting political risk in mining products

For miners entering politically volatile countries, best practices are not merely lip service to regulations, they are guidelines to improve and protect the lives of mine workers and local residents alike. In August, financing advisor Mauro Chiesa offered his six tips for reducing risks that mining projects may face in countries with uncertain political climates. – Michele Beacom

In-situ in sight

The amount of energy required to reduce the ore to a size where minerals can be extracted is enormous. There is enough rejected material generated by the mining process to literally build mountains of waste. The general public’s appetite for minerals is far greater than its stomach for the mines that provide them. When framed this way, in-situ recovery of minerals has a lot to offer. The method is common practice for soft rock mines. Has the moment arrived for its hard rock debut? Christopher Pollon spoke to Hatch’s Doris Hiam-Galvez who is in-the-know about in-situ recovery. – Ryan Bergen

Clear and clean

Water is essential to mining operations, but fresh water is becoming less available. According to the 2018 World Economic Forum Global Risks Report, water crises ranked fifth in terms of global impact. Staring down the reality of a future resource-constrained world, companies are looking for ways to reduce and recycle the water they use. Kylie Williams looked at a number of different projects for our February cover story, including Goldcorp’s Towards Zero Water water-reduction strategy. – Tom DiNardo

Agnico Eagle gets LTE underground at LaRonde

Agnico Eagle’s LaRonde operation near Val d’Or has always used a leaky feeder system for its communication needs throughout the mine, but as the company dug deeper that system was no longer sufficient. Agnico turned to a secure LTE network installed by Ambra Solutions and Ericsson Canada. In March, I went up to LaRonde for a demonstration of how the new system is working out – and got to listen to ACDC underground. – Kelsey Rolfe

A remediation idea takes root

Université de Montreal plant biologist Nicholas Brereton has an idea that could be a real game-changer for mine remediation and cleanup of other environmental hazards: planting willow trees in contaminated sites to remove heavy metals and hydrocarbons. For our May issue, Christopher Pollon spoke with Brereton about why willows are particularly well-suited to this task, and how the trees themselves are a potential source of bioenergy and green chemicals, like antioxidants and essential oils. – Michele Beacom

In deep and on track

In August 2017, Agnico Eagle began mining ore from the Deep 1 zone at its Goldex mine. To get to that point, the Goldex team had to work its way through a maze of financial, physical and geological constraints. CIM Magazine’s Kelsey Rolfe paid a visit to Val d’Or in March and went deep to get the story on the novel solution to the challenge of mining Deep 1. – Ryan Bergen

Tailings to the rescue

In order to avoid an increase of the global temperature by two and half degrees by 2100, the scientific consensus is that society must pull more CO2 from the air than we produce. University of British Columbia professor Greg Dipple may have a solution. According to Dipple, the mining industry could become a major player in helping society achieve this goal by using mining tailings that naturally draw CO2 from the air and trap it into new stone formations. – Tom DiNardo

A digital playground

Testing out new technology at a mine site involves balancing the possibility of major losses if things go wrong against the long-term benefits if they succeed. To reduce the risk of the former, several mining companies are turning to test mines – highly productive mines, cordoned-off sections of operating mines, or dedicated third-party operations – to trial new technologies and processes. For our September/October issue, Joel Barde spoke to people at Vale, Agnico Eagle, Barrick Gold and Norcat about their various proving grounds. – Kelsey Rolfe