A Gewerkschaft Walter mechanical shaft excavator

(This article was originally published in CIM Magazine’s May 2008 issue as part of the “Evolution of Shaft Sinking” series.)

During the 1970 to 2007 time period, there were a number of changes to traditional shaft sinking systems, both in Canada and in other countries around the world. These include:

» the use of shaft jumbos for drilling;

» the use of electronic detonators for blasting;

» the use of hydraulic drills rather than pneumatic drills;

» the use of slurry explosives instead of nitroglycerine-based explosives;

» the drilling and blasting of long rounds utilizing drill jumbos suspended from the work stage;

» equipping the shaft simultaneously with excavation; and

» the development of mechanical shaft excavation systems.

It can be noted that during this period no improvements were made to the mucking, hoisting or concreting segments of the sinking system.

Jumbo drills

Shaft drilling jumbos were introduced in Canada in the 1970s and somewhat later in South Africa. Patrick Harrison & Co. introduced a six-boom “Acme” shaft jumbo at the Pipe Lake shaft in Thompson and a four-boom unit at the Lockerby ventilation shaft near Sudbury in 1972. The introduction of drill jumbos to Canadian shaft sinking was somewhat later than in the United States and Europe because of the popularity of the benching round in Canada. A full-face round was drilled with a shaft jumbo.

At about the same time as the pneumatic drill jumbos were introduced in Canada, the first hydraulically powered jumbo drills were being introduced in the tunnelling industry. However, it was not until the late 1980s that Canadian shaft sinkers started using hydraulically powered drills on their shaft jumbos.

A typical pneumatic shaft jumbo

A typical pneumatic shaft jumbo

In Canada, the “Long Round” shaft sinking system was developed in the late 1980s and early 1990s. This system utilizes a drill jumbo that is suspended from the sinking stage rather than sitting on the shaft bottom. The suspended drill jumbo drills a burn cut rather than a V-cut or cone cut that is normal in shaft sinking. Initially, the cut consisted of a series of closely spaced holes. Dynatec Mining of Richmond Hill, Ontario, pioneered the use of one or more large diameter holes (200 to 250 millimetres) for the cut instead of a series of small holes. A separate ITH drill is used to drill these large diameter holes.

Explosive power

During this time period, most Canadian shaft sinkers changed from electric detonators to non-electric systems. These new detonators are extremely resistant to accidental detonation by static electricity, stray electric currents, radio transmissions, flames friction or impact. Nonel shock tubing is one of non-electric detonating systems presently in use by shaft sinkers. The original Nonel system was first introduced in 1973.

Explosives used in shaft sinking have generally changed from the traditional nitroglycerine-based explosives to slurry or emulsion type explosives. Both slurries and emulsions are safer to use than nitroglycerine-based explosives. Melvin Cook, the founder of IRECO Chemicals, invented slurry explosives in 1956, while emulsions were developed by Atlas Powder in the United States in the late 1960s. Neither of these explosives were adopted immediately by shaft sinking companies, and it was only in the 1970s and 1980s that they became popular. Some shaft sinking companies preferred to use the nitroglycerine-based explosives, despite the fact that they are more difficult to handle.

In the 1990s, a further improvement was made to shaft sinking efficiency – the bulk loading of explosives for shaft sinking. Both explosives manufacturers, Orica and Dyno Nobel, assisted in the development of this method of loading explosives.

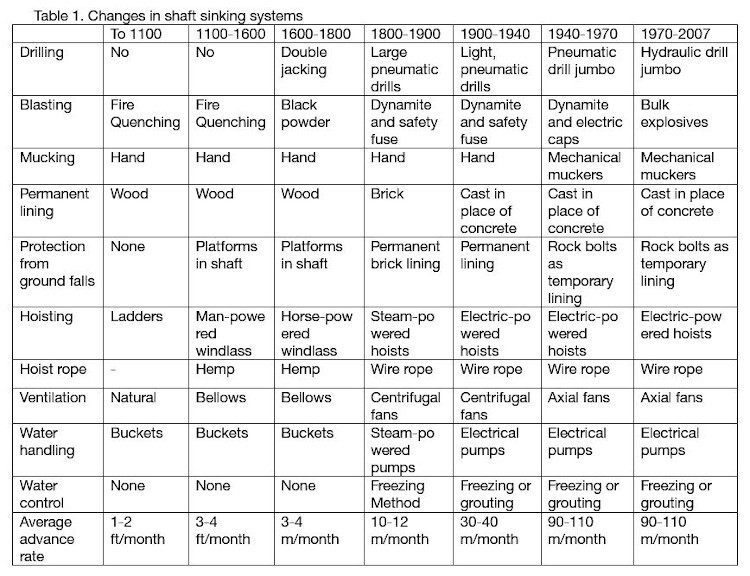

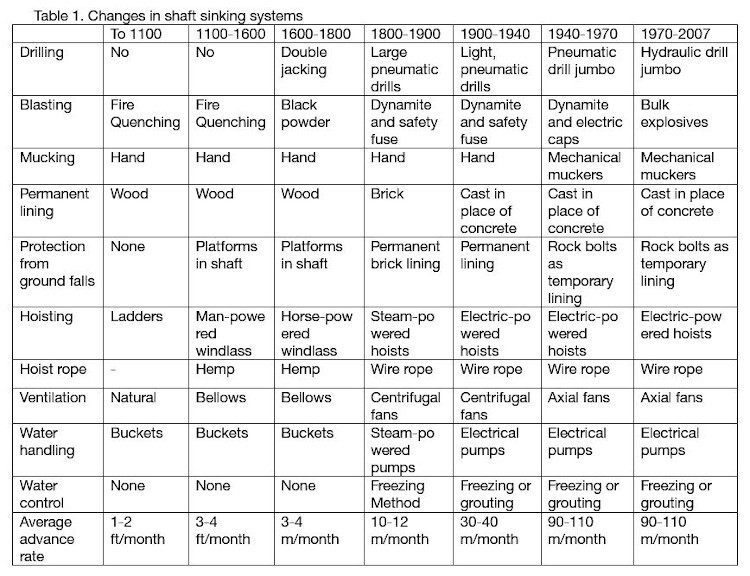

Table 1. Changes in shaft sinking systems

Table 1. Changes in shaft sinking systems

Project techniques

Shaft sinkers around the world have traditionally preferred to sink a shaft bare and then equip it after in a separate operation. At Xstrata’s Nickel Rim project in Sudbury, Cementation Canada was able to safely and efficiently equip the shafts on that project concurrently with shaft excavation.

Large-diameter shaft drilling has been carried out for more than 50 years. Originally developed in Europe, the technique first became popular in the United States on the Nevada Test Site where 1.5- and 1.8-metre diameter shafts were drilled for the underground detonation of nuclear devices in the 1970s. After a considerable amount of modification, the rigs were able to drill a 1,000 foot deep shaft in 20 days – an advance rate of 50 feet (or 15 metres) a day.

A Hughes large-diameter drill rig

A Hughes large-diameter drill rig

One of the most interesting shaft drilling projects during this period was the 14 foot (4.3 metre) diameter shaft drilled in Australia at the Agnew Nickel mine. The shaft was drilled to a depth of 750 metres in 328 days in rock ranging from 30,000 to 59,000 pounds per square inch compressive strength.

Originally, modified oilfield equipment was used for drilling the shafts. However, specialized equipment has been developed to improve efficiency. Most of the drilled shafts in North America during this period were for ventilation shafts in the Appalachian coal mines. Blind-hole drilling for ventilation shafts was also popular in Russia in some of the other countries of the former Soviet Union.

Shaft boring machines were developed by the Wirth company in Germany and have been designed both as reaming V-moles and full-face excavators. The reaming models have been much more popular than the full-face excavators; however, they do require that there be bottom access to the shaft. According to Wirth, 60 projects have been completed since 1971. Unfortunately, the overall time required to complete a shaft using this technique is no faster than conventional sinking.

In relatively hard rock, the speed of the various operations might be as follows:

» pilot hole drilling – 15 m/day

» enlarging pilot hole to 1.8 metres – 7.5 m/day

» enlarging to 6.5 metres with V-mole – 6 m/day

Assuming a 1,000-metre deep shaft and neglecting the time to set up the V-mole, a completed shaft would take 368 days – an advance rate of 2.7 m/day – which is no faster than conventional sinking.

New machines

There have been other mechanized shaft sinking machines developed. Gewerkschaft Walter, a German shaft sinking contractor, developed a shaft sinking machine that was used in the sedimentary rocks overlying the German potash beds and the salt itself. Excavation was with a rotating cutter head somewhat similar to a roadheader. Mucking was by means of a vacuum system into conventional sinking buckets.

Another shaft sinking machine was developed by a Robbins/Redpath joint venture under a USBM grant between 1975 and 1980. The material was excavated using a rotating cutter head similar to that used on the Robbins Mobile Miner. Broken material was loaded into conventional sinking buckets with a Cryderman-type loader. The goal of the project was to achieve a sinking rate of 25 feet (or 7.6 m) a day in a 7.3-metre diameter shaft. At the test site in Bessemer, Alabama, a shaft was sunk to a depth of 197 metres using the Robins/Redpath machine, but advance rates were much slower than expected and the project was abandoned.

Perhaps the most encouraging event regarding mechanical shaft sinking is the fact that the German tunnel boring machine manufacturer Herrenknecht A.G. developed a shaft sinking unit capable of excavation in soft rock. Herrenknecht is the world’s largest manufacturer of tunnel boring machines and manufactured three units that were used to excavate shafts ranging between 2.5 and 8.0 metres in diameter.

The machines have been utilized on tunnelling projects in Kuwait, Indonesia and Russia. Following is a description of the 300-kilowatt unit that was utilized in Kuwait:

» The Herrenknecht shaft sinking unit consists of two main components – the 78-tonne lowering unit and the 59-tonne shaft boring unit.

» The shaft boring machine is assembled in a launch section at the top of the shaft and then starts excavating the ground mechanically with the boring head rotating at a speed of 85 rpm.

» The lowering unit is anchored securely to the shaft collar at the surface.

» The shaft is lined with pre-cast concrete segmental rings. The segments are connected to each other on the surface and pushed vertically into the shaft by jacking units mounted on the lowering unit.

» To balance the surrounding groundwater pressure, the shaft is then flooded with water during excavation.

» The excavation of the material underwater is comparable to the operation of a slurry shield type of tunnel boring machine. The rotating cutter head excavates the material and the mixture of excavated material, and water is pumped to a settlement tank on the surface, where the material is separated. A machine operator continuously monitors the process from a control room on the surface.

While the machines are certainly not applicable to shaft excavation in hard rock, Herrenknecht began working towards developing a mechanical shaft excavation machine.

Safer sinking

There were a number of notable improvements in shaft sinking techniques during this time period.

They contributed to a more efficient and safer shaft sinking operation, but average shaft sinking rates did not increase appreciably. The one exception to this statement was the development of a system to allow equipping of the shaft concurrently with excavation on the shaft bottom. This was a major step forward and was recently achieved by Cementation Canada at the Nickel Rim project.

There were advances in the mechanical excavation of shafts, but the advance rates of the mechanical excavators in hard rock were no faster than conventional shaft excavation techniques.

Unfortunately, 1970 to 2007 was the only time period to date where sinking rates were not increased drastically through some improvement in technology. One very important aspect of shaft sinking did improve, however, and that is safety. Accident rates on shaft sinking projects dropped appreciably over the period.

ABOUT THE AUTHORS

Vern Evans was previously a general manager at Mining Technologies International. He is currently a senior consultant at Stantec.

Charles Graham was previously the managing director of CAMIRO Mining Division. He is currently retired.

Part 7 - Shaft sinking from 2007 to 2020